Page 18 of 20

Re: My 181 - Kubel - Trekker - Thing

Posted: Fri Jan 09, 2015 10:35 pm

by Tom Bishop

Howzit Brendan. Ya, i'm Trying to get some of the Things I started out of the garage.

Well, the motor started today with much spluttering. It turns out 2 injectors aren't working. I believe this happens if they stand.

BTW these are Ford Injectors. Damn, with Ford Parts in a Beetle motor, if this engine doesn't leak oil there is something wrong.

@jolas Thank You.

Would anybody here happen to have a map for the Spitronics Mercury ECU and Coil controller for a stock 1600TP motor?

Re: My 181 - Kubel - Trekker - Thing

Posted: Sat Jan 10, 2015 6:02 am

by Tony Z

Good show Tom. sounds like you came right with the plug leads

are you looking for a spark map?

Re: My 181 - Kubel - Trekker - Thing

Posted: Sat Jan 10, 2015 7:50 am

by Dawie

Nice project.

I doubt that your injectors went faulty from sitting a short while. (I knew Ford parts are bad, but they cannot be THAT bad). Injectors from other makes can sit unused for many years without going completely faulty/not spraying at all. Could the issue be with the wiring? Or maybe your programming does not enable those injector outputs.

That rpm-sensing sprocket on the pulley. Knowing that you are into bicycles, is that sprocket from a bicycle?

Re: My 181 - Kubel - Trekker - Thing

Posted: Tue Jan 13, 2015 9:40 am

by Tom Bishop

It Runs.

A guy by the name of Lenard helped me get this motor going.

2 Injectors were rusted. These were the first parts I bought for the conversion. I found the receipt dd 3 Jan 2011 so they had been sitting for quite some time. Lenard got them going again by pressing a pencil engraver with a blunt point against them and vibrating them back to life. He reckons the fluid left in the injector for testing proposes causes them to rust.

You should see the Wrangler Jeep he has just built up for a customer. 6,? Litre Chev motor, some sort of gear box, modified suspension and sitting on very large tyres. Tells me it does 0-100 in 4 secs and accelerates to 200 after which he taps off as the jeep becomes unstable.

Imagine working on the Jeeps motor and then on this Beetle motor. Yawn.

Re: My 181 - Kubel - Trekker - Thing

Posted: Tue Feb 10, 2015 4:56 pm

by Tom Bishop

Look what the

Thing's rev counter can now do. The needle goes to 8k no problem.

This is an stock 1.6 motor with only fuel injection and Spitronic management system fitted.

.

.

.

.

.

.

.

.

.

.

.

Of course this was before I configured the managements rev output to be 4 cylinders.

Re: My 181 - Kubel - Trekker - Thing

Posted: Wed Feb 11, 2015 8:20 am

by Thumper

That's a cool trick. Do you need ear protection when the revs are that high?

Re: My 181 - Kubel - Trekker - Thing

Posted: Wed Feb 11, 2015 12:10 pm

by Tony Z

Running wasted spark Tom??? It would have been quicker to flip the switch on your rev counter to 8cyl... Might have worked.

Re: My 181 - Kubel - Trekker - Thing

Posted: Wed Feb 11, 2015 10:52 pm

by retrovan

At 8K rev's,

all you only still need is a bumper sticker........

"beware of flying parts" ....

Nice one.

Herman

Re: My 181 - Kubel - Trekker - Thing

Posted: Thu Feb 12, 2015 10:18 pm

by Tom Bishop

Kubel all ready for George, almost.

After A-Framing it Home from my Dads garage, the left rear wheel is getting warm.

I'll sort it out in the morning.

@Tony. You simply set the rev pulse output, through a drop menu, to what ever you like. Everything in this setup is soft and you set it up how you want it to behave. To dismantle the dash would have been a shlep. You cant access the back of the gauges through the bonnet. The dash flips forward and closing it again is the problem. Lots of wires ( as the fuse box sits on the same panel) a hazard switch , a lights switch, and a rev counter needs to fit in a very small place.

Re: My 181 - Kubel - Trekker - Thing

Posted: Fri Feb 13, 2015 6:17 am

by Tony Z

Enjoy George. i hope the Kubel makes it there and back without any issues

Re: My 181 - Kubel - Trekker - Thing

Posted: Fri Jan 06, 2017 9:37 pm

by Tom Bishop

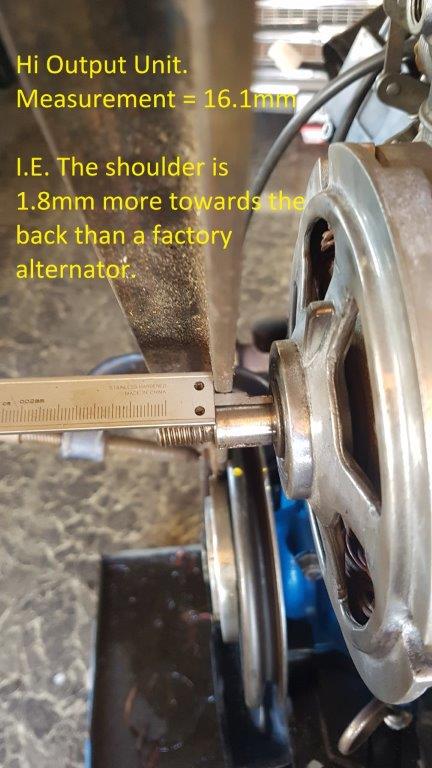

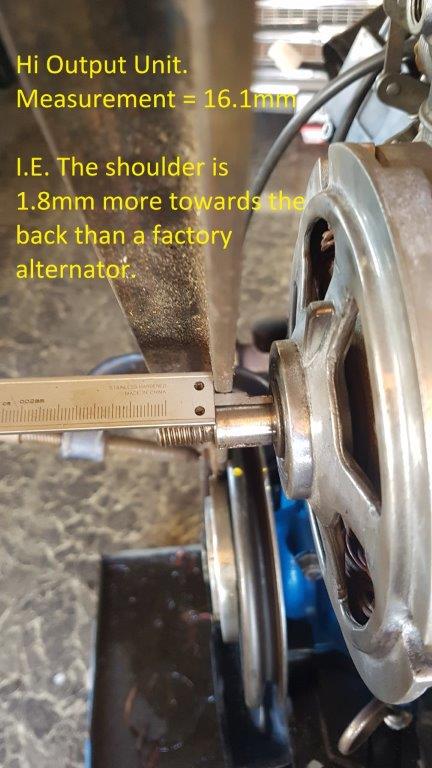

Need a some Advice:

I'm trying to fit my Hi Output Alternator again.

The last time I had it running the shoulder on the shaft chewed a recess into the aftermarket chrome pulley and it ended with the pulley severing the arms that support the alternator bearing.

The arms were fixed and this time I’m taking measurements. From the attached pics you can see there is nearly a difference of 2mm between the two shafts.

Could this be the reason that the shaft ate into the pulley or was the aftermarket pulley inferior and the 2mm is ok? I will be running the factory alternator pulley this time.

Re: My 181 - Kubel - Trekker - Thing

Posted: Fri Jan 06, 2017 10:23 pm

by retrovan

after market pulley are junk

Better try to find a OE pulleys from someone here on the forum

Herman

Re: My 181 - Kubel - Trekker - Thing

Posted: Sat Jan 07, 2017 12:28 am

by Dawie

Many, many moons ago i bought an aftermarket type 1 alt pulley, (it looked nice). Soon realised that it was a misfit... too much clearance/slightly loose on the shaft, wrong dimensions, etc. So i bought a used one instead, and chucked away the unusable aftermarket one.

Re: My 181 - Kubel - Trekker - Thing

Posted: Sat Jan 07, 2017 5:30 am

by Tony Z

There is one aftermarket pulley which I use which IMO is the best pulley that can be bought for the std V-belt style. But thats another topic.

Tom, I think you need crank gear spacers, they are around 2mm thick and slip onto the crank before you put on the pulley. This will move the crank pulley back 2mm and give you back your 18mm gap that you have on the std alternator.

Re: My 181 - Kubel - Trekker - Thing

Posted: Thu Jan 12, 2017 9:26 pm

by sean

That pulley is 95% of the problem. Throw it away. I have had the exact same experiences as yours here and it was all because of new pulleys. Find an original one and your problem will be solved.

@ Tony, where do you get this quality item you speak of? I need some.

Here are some pics of original ones. Take note of the centre base.

Here are some Chinese numbers, all different but have had exactly the same problem (at the same time destroying an alternator bearing carrier.)

Look at their center base. They seem to have this slight recess but this allows the pulley to now sit closer to the housing. Within a period of days, the alternator shafts actually manages to compress that pulley and it moves in damaging the housing. Take a special look at the chrome one below. That lasted 2 months. It first started grinding into the alternator housing after 1 month, so I added a collar/spacer behind the pulley to space it further away, 1 month later and that collar just pushed in another few mm causing the same problem again, almost as if the pulley is made from a very soft material....