fig wrote:I don't know anything about relative efficiency of different filters, but I swear by oil bath filters for African conditions.

When crossing the Nubian desert in Sudan in the ZebraBus, the oil bath became an almost solid cake of oily mud, with just the thinnest layer of oil on top. Despite that, I couldn't see or feel any grit in the pipe between filter and carb, or in the carb. After that incident, I made a point of cleaning the filter more often.

The following chart, which formed a part of the Canadian Fish carburettor brochure, compares the degrees of engine wear, associated with a micronic air filter and an oil-bath air cleaner.

![Image]() Donaldson TopSpin™ air pre-cleaner

http://www.donaldson.com/en/engine/supp ... 000207.pdf

http://www.odms.net.au/files/organise/d ... 111107.pdf

Donaldson TopSpin™ air pre-cleaner

http://www.donaldson.com/en/engine/supp ... 000207.pdf

http://www.odms.net.au/files/organise/d ... 111107.pdf

In the following topic thread, of the Australian Kombi Club forum, Steve (aka Kombi Rescue), remarked that the high air intakes, on the post-1961, Australian specification VW Kombis, arose because of the Australian VW engineers in Melbourne, smearing grease on the outside of the rear, side panels and then noting where the dust mostly adhered.

Bay Tech Clinic > Body > Air Scoops

http://forums.kombiclub.com/showthread.php?t=19823

It is doubtless better, to induct the least dusty ambient air available, into the engine compartment, so that less dust needs to be filtered out. The celebrated Arthur Barraclough, modified his British specification, 1970 VW "1600" Type 2, by sourcing the engine's combustion air, from inside the main passenger cabin.

In a book, I recently borrowed from my local public library, I came across the following information about air intakes and combustion-air, air filters, for the Australian & South African specification, VW Type 2 Kombis, plus Single-Cab & Double-Cab Pickups.

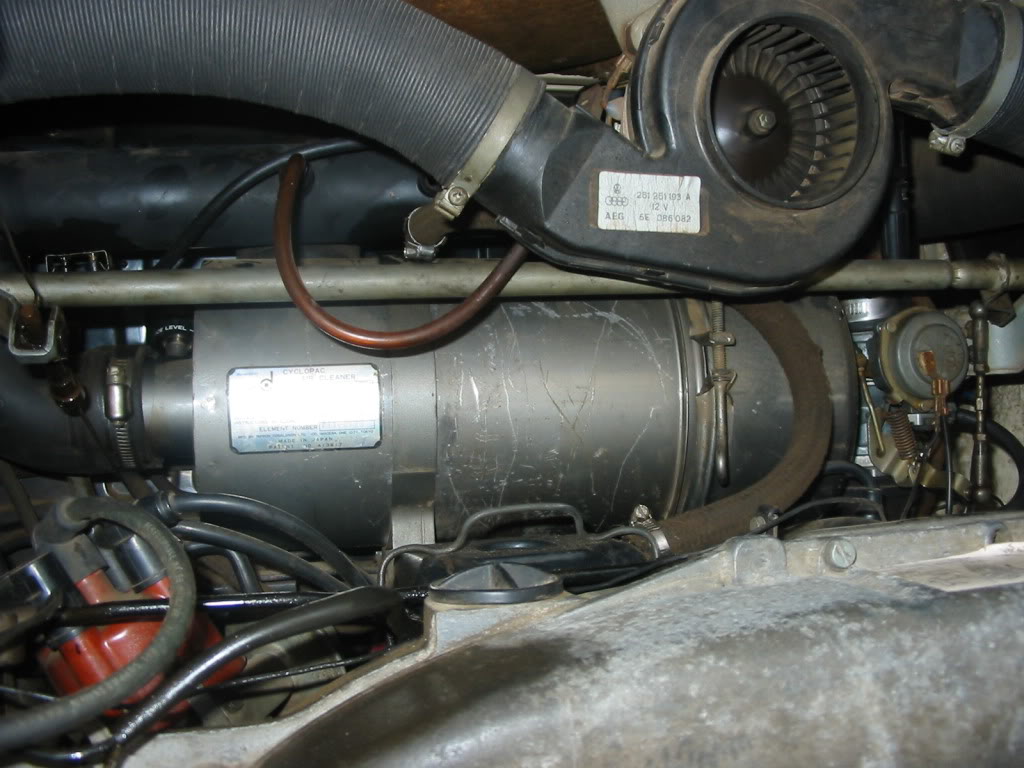

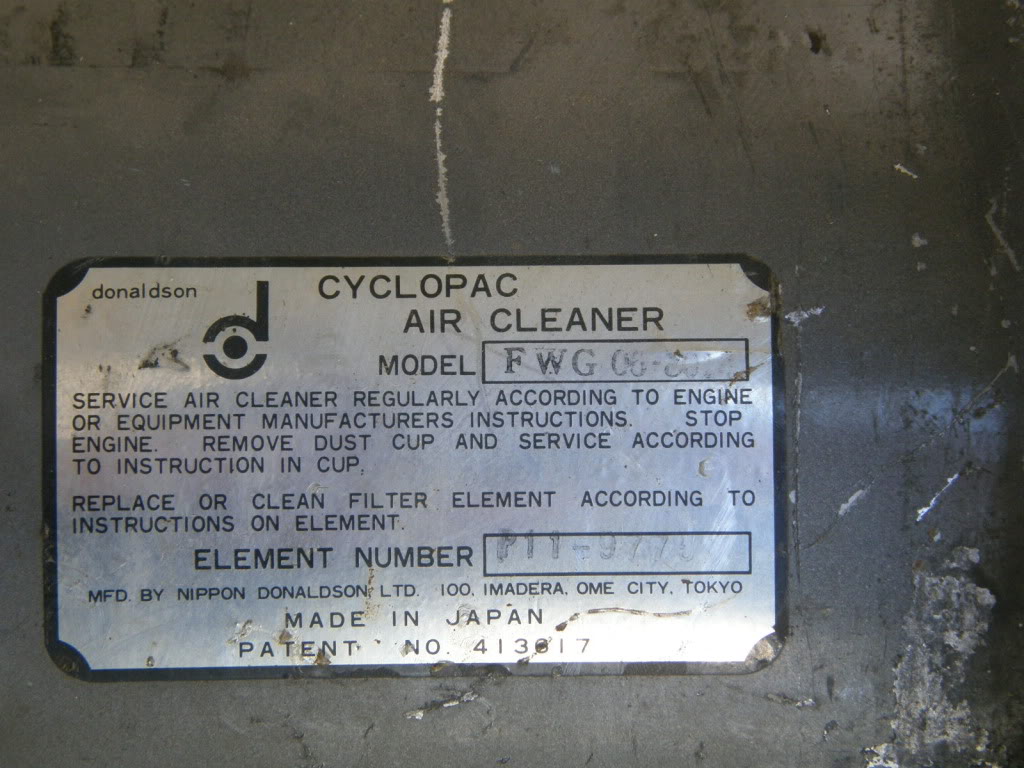

It seems that in Australia, a Donaldson air filter was introduced, for pre-1968 VW Type 2s, as a VW dealership supplied, retro-fit kit, sometime prior to mid-1962 and became standard equipment from mid-1962 onward, so presumably something similar was specified for the 1968~79 VW 1600 Type 2s!?!

David Eccles, "VW Transporter & Microbus - Specification Guide 1950~67", The Crowood Press, 2002, ISBN 1-86126-509-3 [Chapter 4 - Specification Detail Changes Month by Month, Pages 23~36].

Illustrated on Page 35

Australian 1962~66 VW Type 2 - nine, long, outward facing, horizontal, engine-compartment, air-intake, cooling slots, above the swage line (i.e. at same level as side windows)

Australian 1966~67 VW Type 2 - two sets of nine, short, outward facing, horizontal, engine-compartment, air-intake, cooling slots, above the swage line (i.e. at same level as side windows)

David Eccles, "VW Transporter & Microbus - Specification Guide 1950~67", The Crowood Press, 2002, ISBN 1-86126-509-3 [ Chapter 6 - Optional Equipment (M Codes), Pages 41~45].

Extract from Pages 41 & 43

M004 | Dust-free air intake (Pick-Up)

M010 | Dust filters for engine compartment

M155 | Cyclone air filter (export)

M156 | Larger oil bath air filter

Illustrated on Page 44

Cab front peak, with dust-free air intake (M004) for engine compartment of Pick-Up

David Eccles, "VW Transporter & Microbus - Specification Guide 1950~67", The Crowood Press, 2002, ISBN 1-86126-509-3 [ Chapter 9 - Transporters Assembled or Built Overseas - Australian Transporters, Pages 54~58].

Extract from Page 55:

« The actual production vehicles built and assembled at Clayton had some minor differences to the Hannover vehicles which are unique to VWA-built Transporters. The most obvious external difference is the positioning of the row of air vents above the swage line - a climatic necessity in the hot, dusty Australian environment. This was introduced in 1961/62 and used the new body-shop facilities. In 1966, this became a double row of air vents above the swage line. The CKD kits had the vents below the swage line, as normal. »

Extract from Pages 56~57

« Australian buses had to cope with extreme heat and dust conditions. Many Australian roads were (and still are) unsealed dust roads, and for the VW Transporter, designed with an air-cooled engine located at the rear with cooling air being drawn in from the air vents, dust became a major problem, leading to overheating and engine failure! To get around this problem many owners had the dealership or local garage fit a Snorkel device from the inner upper rear body panels with the air-intake grille and coupled these with large capacity hoses to the engine filter. Many buses were also fitted with the larger oil bath cleaner (M516) or the cyclone air-filter (M155) options. »

« There is also a large-capacity paper cartridge filter, the 'Donaldson Type', which was available as an official kit to be fitted by VW dealers. On 3rd July 1962, the paper air-filter arrangement on all Transporters became standard, with the paper air filter housed in a metal case and fitted to the elbow. This meant that the air pre-heating flap valve and hose were dropped, and the outlet in the heater box and the grommet hole in the engine front cover plate weesealed with metal plugs. The fuel filler flap was also fitted with an extra rubber seal to increase dust entry protection. »

« Quick to recognize the dust problem, VWA also utilized a special conversion to the body on the most abused of the commercials - the Pick-Up. The solution - duct clean air from the front instead of via the vents at the back! This was in fact an existing Hannover Special Equipment option (M004), but became standard Australian Pick-Up specification from 1962. »

« This special version of the Single Cab Pick-Up had a double roof with a second roof panel, allowing clean air to enter above the windscreen. This was separate from the fresh air into the cab, and necessitated extra vents under the roof peak. Cooling air could then be ducted down the back of the cab and under the bed directly into the engine - dust and overheating problems solved! Pick-Ups like this are instantly recognizable by the slightly bulbous cab shape and the absence of cooling vents at the rear. »

David Eccles, "VW Transporter & Microbus - Specification Guide 1950~67", The Crowood Press, 2002, ISBN 1-86126-509-3 [ Chapter 9 - Transporters Assembled or Built Overseas - South African Transporters, Pages 61~63].

Extract from Page 61

« A cyclone air filter is usually standard, but some Double Cabs have a very unusual arrangement with a pair of ducts mounted to the rear sides of the drop gates. These take in air from the top of the drop gates and duct it into the engine through slots above the engine bay. Earlier versions of Double Cabs with this extra cooling-air arrangement are found with the standard cooling vents still in place, whilst later ones are similar to the Australian version with smooth corners. »

Extract from Page 62, referring to a British registered, South African specification, 1966 VW Kombi, illustrated on Page 61.

« Other interesting features, which are optional equipment, include the cyclone air filter (usually a standard option in hot, dusty climes) and extra air ventilation fans in the roof of the load area. An unusual after-market addition is the extra cooling vents, each with a chrome cover. They can be flapped open to allow more cooling air to be forced into the engine bay. »