Page 1 of 3

A few pics of a new project

Posted: Sat Mar 25, 2017 6:24 pm

by Tony Z

I thought I'll throw a few pics together of something small I have ongoing right now.

I'll put it together in the relevant thread when the time comes...

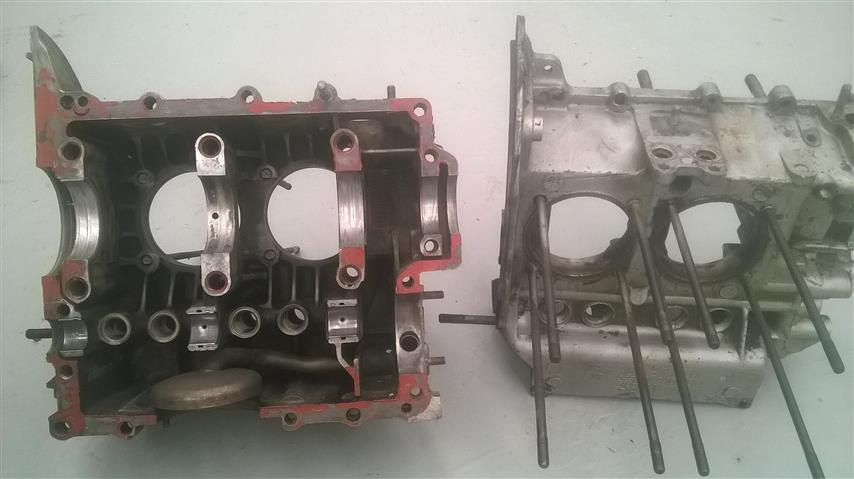

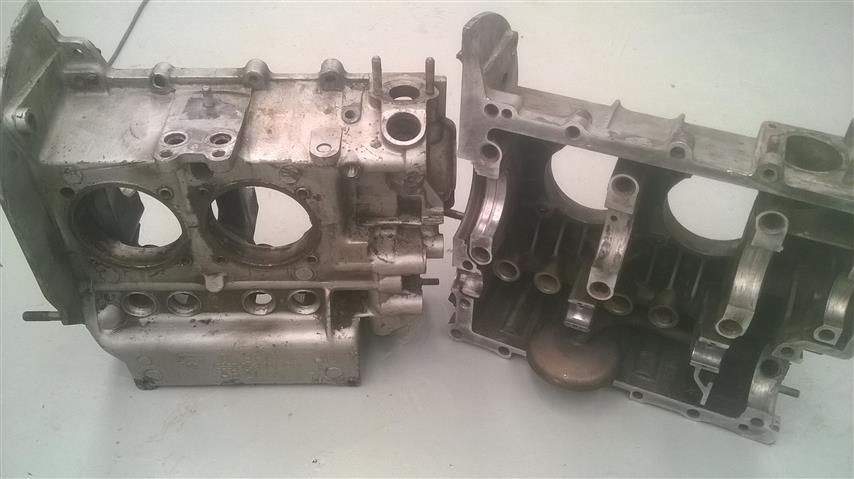

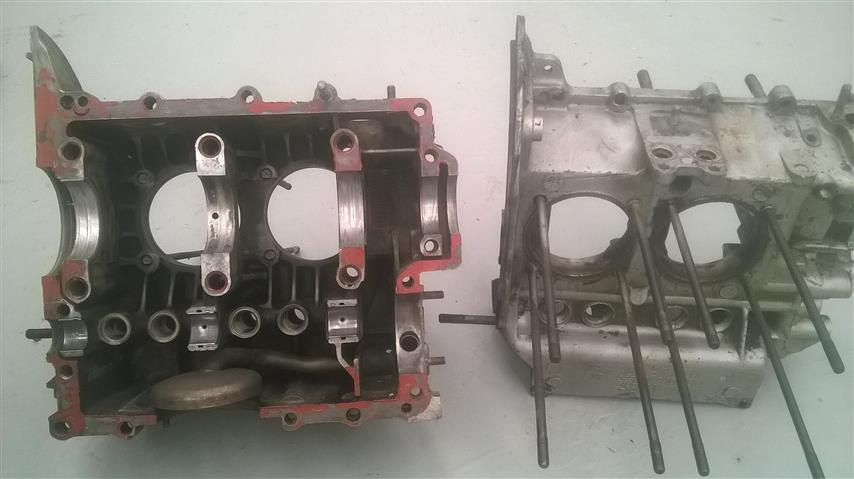

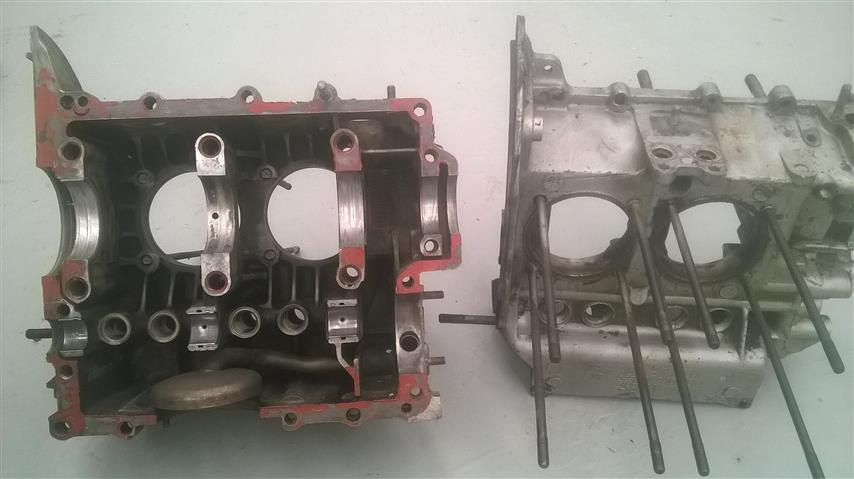

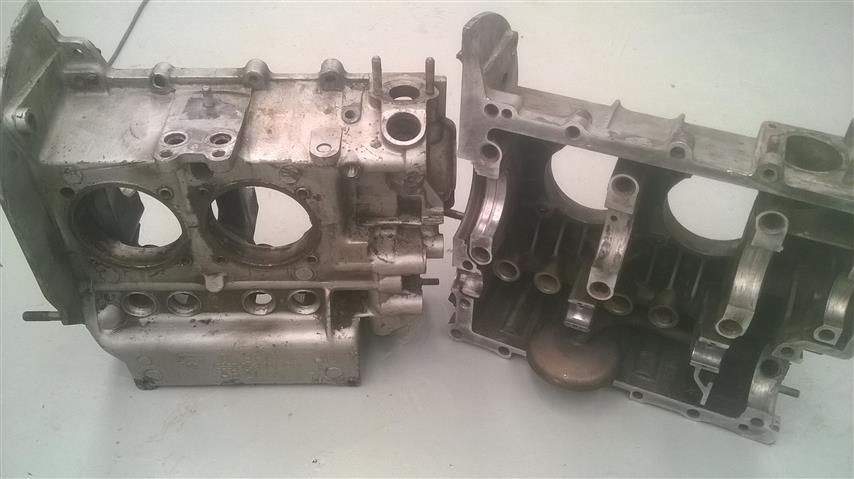

Take case and give it a preliminary wash

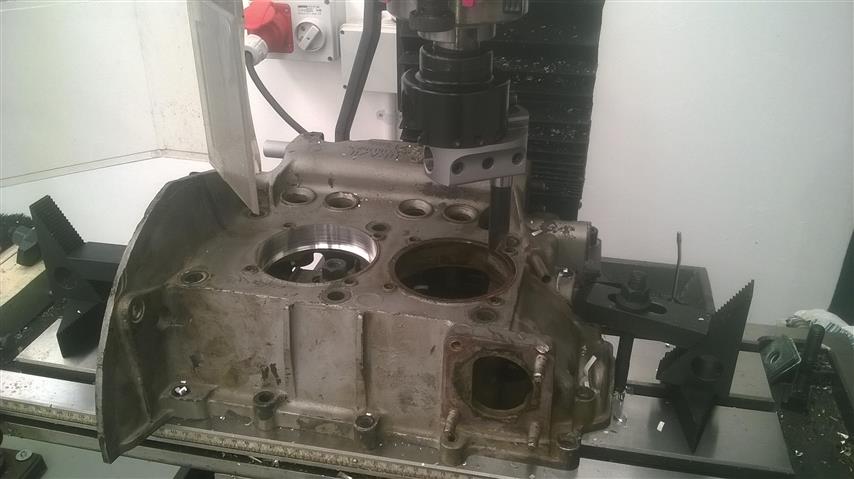

strip case so it fits on the mill

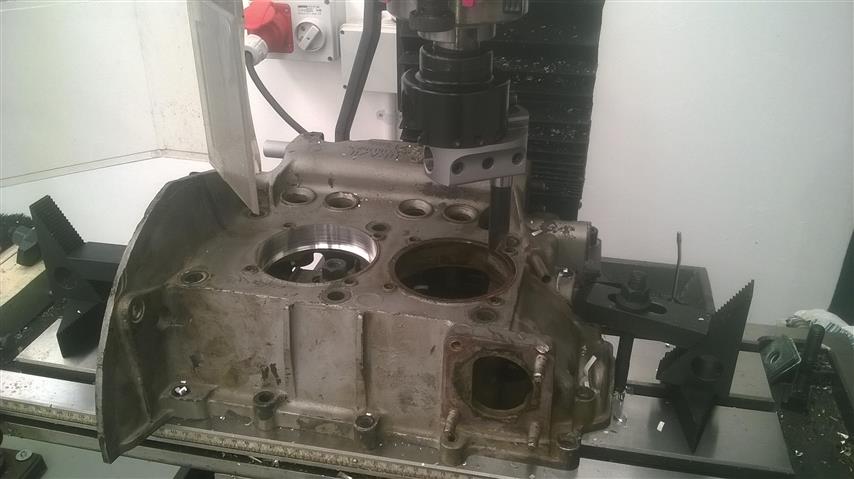

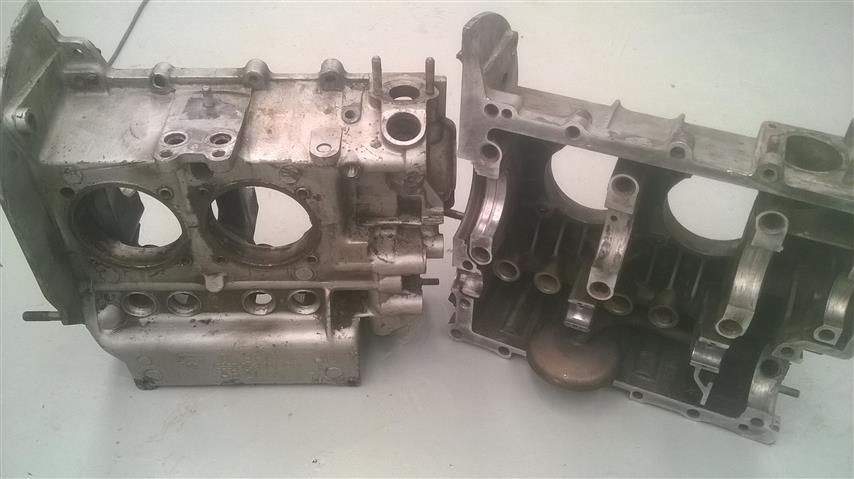

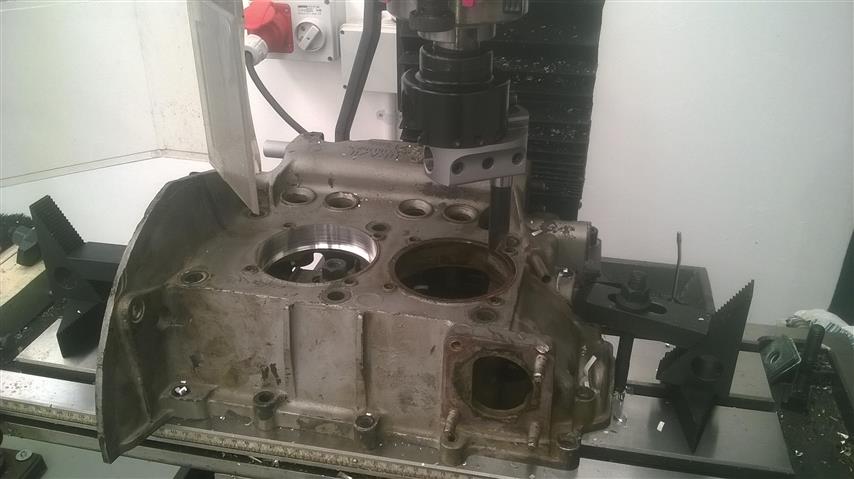

put case on mill

clock up and cut case

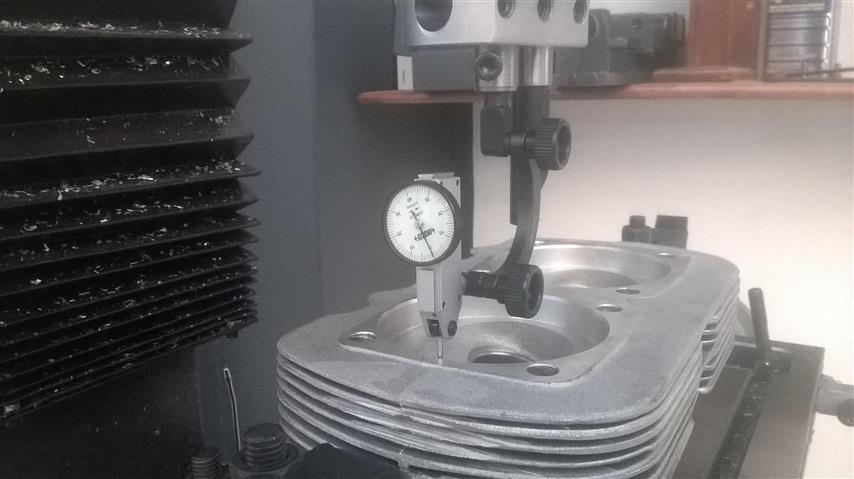

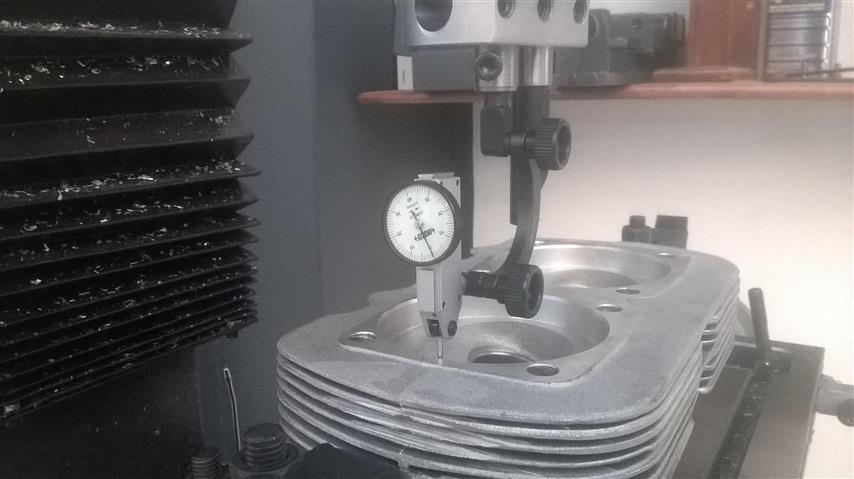

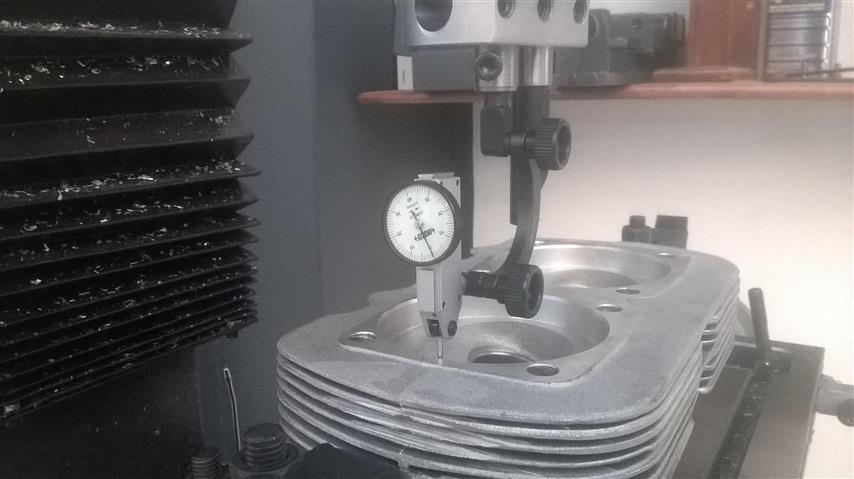

put heads on mill and clock up

cut heads for 90.5mm cylinders

Re: A few pics of a new project

Posted: Sat Mar 25, 2017 6:32 pm

by Tony Z

then when doing a few smaller touches I noticed that the thrust face looks a bit more worn than I first thought...

turns out it is already past its minimum size of 20mm. It measures 19.8mm already.

So, will have to see how I go from here.

As of now, thats where I am with this project.

Re: A few pics of a new project

Posted: Sat Mar 25, 2017 7:57 pm

by retrovan

You have the machinery, Why not fit an insert and set it back to Zero.

Should the rest of the case be OK, this should be Simple to do.

Specially for the Big Z

Hope you come right.

Herman

Re: A few pics of a new project

Posted: Sun Mar 26, 2017 12:43 am

by Tony Z

that is exactly my plan Herman.

Re: A few pics of a new project

Posted: Mon Mar 27, 2017 11:31 am

by Wentzel

Looking good Tony. Having all the tools and know how for this must be great.

What is the plans for the engine?

Re: A few pics of a new project

Posted: Mon Mar 27, 2017 11:56 am

by acpaterson

Looking good Tony.

Re: A few pics of a new project

Posted: Mon Mar 27, 2017 4:37 pm

by johanb

All the best with your project meneer

Re: A few pics of a new project

Posted: Mon Mar 27, 2017 5:01 pm

by Tony Z

Thanks guys. I'll reveal more as the project progresses - its still a long way from done.

Re: A few pics of a new project

Posted: Tue Mar 28, 2017 6:31 pm

by Tony Z

Managed to get a bit done today. Not all went according to plan, but its all par for the course.

Put all the case bolts back in excluding the head studs.

Then bolted the case together and torqued it down.

Out with my line bore tools

The case is cut for standard mains, but I can see the #1 (thrust) bearing will need more than a 0,5mm cut.

But instead of moving straight to a 1mm cut, I went for the 0.5mm cut first so that I have a good seating point to cut the thrust face.

I am not fond of the way the thrust cutter marks the journal, so it should to be done before the line bore. Anyway, my logic was to give it a bigger, rounder seating area by boring to 0.5mm then doing the thrust cut and then reboring to 1mm which should be final size.

0.5mm line bore

Thrust block inserted and cutting of the thrust face

You might notice that the thrust face isnt 100% cleaned up. That is due to the amount of wear of the face. I cant cut it further as I have no secure way of locating the thrust cutter and keeping it level if it doesnt rest against the case from the inside. But it does cut a larger diameter than the previous cut, so it is still nicely cleaned up enough to support the bearing.

1mm cut - unfortunately, this still didnt clean up the bearing journal

So, on to a 1.5mm cut. This cleaned it up nicely.

O yes, nearly forgot. @Wentzel gave me a tip to use a Golf 1100 ring as a spacer. I bought myself a ring pack for a 20thou oversize 1100 golf and this fits nicely. Before you guys go on about price, this ring pack was just under R150. For that price I couldnt say no.

here it is fitted loose using the top compression ring

Re: A few pics of a new project

Posted: Tue Mar 28, 2017 7:29 pm

by retrovan

Good work there Sir,

Will be running in no time.. I'm sure

Herman

Re: A few pics of a new project

Posted: Tue Mar 28, 2017 8:48 pm

by Tony Z

yea, its coming together nicely. But there is still plenty to do

Re: A few pics of a new project

Posted: Wed Mar 29, 2017 7:13 am

by Wentzel

Glad to help Tony but as I said I got the tip on the forum also. If I remember it came from Armand.

From what I read/heard even vw used spacers on that main sometimes when rebuilding.

Re: A few pics of a new project

Posted: Fri Mar 31, 2017 5:30 pm

by Tony Z

Not much more progress made.

Wasted a few hours driving to all the spares shops who usually have bearings and spent ages phoning around to the guys who might have bearings. Needless to say that the size I need isnt available in SA from any of the local guys. So, I've got a set on its way from USA.

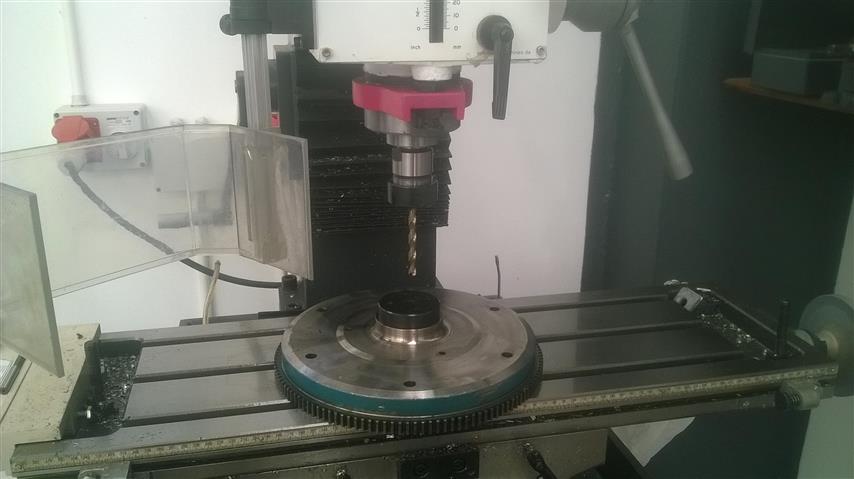

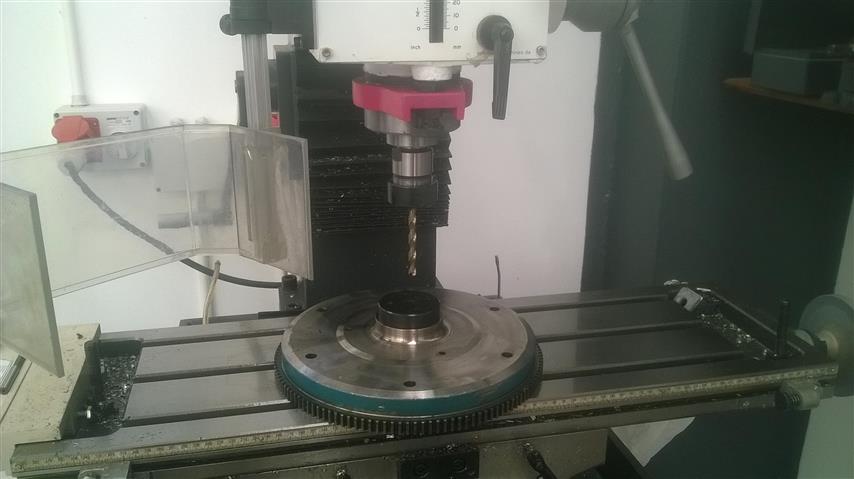

The only other thing I have managed to do is to 8-dowel the flywheel.

Take a normal flywheel in good condition

Put it in the milling machine, clamp it down and drill it out for another 4 dowel pins. This helps in keeping it in place when the engine is capable of producing a bit more hp.

Final result

As the new holes are made to an exact size, it is best to do a pilot hole and then ream the hole to the correct size needed.

And to ensure that the drill and reamer run properly true, dont even consider using a drill chuck. This is where you pull out the collet set to ensure that it all runs properly true.

Re: A few pics of a new project

Posted: Fri Mar 31, 2017 5:32 pm

by Tony Z

And for those asking, I have decided that this engine does not need the flywheel lightened, so it is staying stock weight.

Re: A few pics of a new project

Posted: Fri Mar 31, 2017 6:25 pm

by retrovan

Whoow... Thats a lot of weight of you mine.......

Nice work as always Sir.

Always regret having sold my machining shop with all the great "Toys" in it.

Oh well, at least now I can share your Joy as you go along.

Thanks

Herman