Blitzkrieg wrote:Tony, what induction are you using for your 2332?EFI or big slurpy Webers?

Tony Z wrote:48 IDF webers

A few years ago at a local autojumble, I had the opportunity to purchase a pair of large-bore, down-draft Weber carburettors, for the princely sum of £25, but decided against it, on the grounds that they would be too large for my 1911 cm³ displacement, VW 17/1800 Type 4 style hybrid engine.

Tony Z wrote:In simple terms, deckheight refers to the distance that a piston is away from the end of the barrel when its sitting at top dead centre (TDC).

I then also added various bits of shim stock that I had cut to size until I ended up with a deckheight of 1.05 mm.

On a side note, the deckheight does seriously influence the quality of the combustion process. A large deckheight leads to poor mixing of the air fuel mix and a slow burn, which does tend to promote detonation and slightly higher cylinder head temps. A tighter deckheight should improve engine efficiency and cylinder head temps.

The area to aim for is a 1.5 mm deckheight or slightly less. Try not to go lower than 1.2 mm unless you have top notch equipment inside the engine as things do stretch when at speed and you dont want the piston kissing the valves or the head. I have heard of guys running down to 0.7mm deck heights, but their conrods cost more than I would like to imagine just to reduce the stretch.

If you regard

a deck height of 1•5 mm or slightly less, to be the preferred clearance, why did you adopt

a deck height of 1•05 mm, on your own engine?

The following two books, dedicated to rebuilding or modifying, VW air-cooled engines, include these comments about deck height clearance:

Tom Wilson, "How to Rebuild Your Volkswagen Air-Cooled Engine", HP Books, 1987, ISBN 0-89586-225-5.

Chapter 7 » Engine Assembly » Page 131 » Set Deck Height

« How Much? - Allowable deck height varies from 0•040~0•080 inch (1•0~2•0 mm). Most cylinder and piston kits are designed to give 0•060~0•070 inch (1•524~1•778 mm) on a stock case. Optimum is 0•055~0•065 inch (1•400~1•650 mm), if you feel like tinkering. »

Bill Fisher, "How To Hot Rod Volkswagen Engines", HP Books, 1970, ISBN 0-912656-03-4

Section 13 » Cylinder heads » Page 46 » Stock Head Description

« VW's ability to use higher-than-stock compression ratios is seriously limited by a large clearance (typically 0•070 inch = 1•78 mm) between the combustion chamber's flat section and the top of the piston . Reducing this "deck" clearance provides improved "squish" or "quench" as originally discovered by Ricardo in 1922. By assembing the engine so that the flat portion of the head is separated from the piston crown by only 0•040 inch to 0•050 inch (i.e. 1•016 mm to 1•270 mm) at TDC, squish is improved to increase turbulence. »

« Increased turbulence insures reasonably complete combustion of the mixture because complete combustion cannot occur at very high RPM unless the mixture is in a state of violent agitation. The cooling effect of the piston crown and the flat surface of the head combine to "quench" any "wild burning" which might start in this areaa farthest away from the plug - thereby helping to eliminate detonation. »

Another engine-building book, which mentions air-cooled VWs, in various contexts, offers the following general advice re deck-height clearance:

A. Graham Bell, "Performance Tuning in Theory & Practice - Four Strokes", Haynes Publishing Group, 1981, ISBN 0-85428-275-6.

Chapter 8 » The Bottom End » Pages 158~159

« To assist in equalising compression and combustion pressure, the crown of every piston must rise to the same point in each cylinder. This is called the deck height of the piston. In a racing engine we would want to be running minimum deck clearance to assist cylinder scavenging, and to up the compression ratio. A good solid motor with steel rods can run with a minimum of 0•040 inch (i.e. 1•016 mm) clearance between the piston crown (not the compression lump) and the squish area of the head. ..... »

« Aluminium connecting rods stretch more at high revs and aluminium has a greater coefficient of expansion than steel, so we would need at least 0•070 inch piston to head clearance. Engines that have steel rods but suffer block flex or crankshaft whip (e.g. VW), will require 0•060 inch (i.e. 1•524 mm) clearance. »

In September 2000, I met a chap by the name of John Wright-Bailey, at the Essex VW Club Show, with whom I had stopped to chat, about his 1978 VW 1600 Type 2, Zenith campervan, converted in Germany. He claimed to have been an engineer, who at one time was extensively involved in developing air-cooled, two-stroke, motorcycle racing engines. He further claimed to have rebuilt his otherwise factory-stock, 1584 cm³ AS-Series, VW Type 1 style engine, using standard-sized, stainless steel valves, a compression ratio of 8•5 : 1 and a deck height clearance of 0•030~0•032 inch (i.e. 0•762~0•813 mm), which was said to run cooler than the factory-stock engine and fuel economy of more than 27 mpg.

When I was contemplating the design parameters of my 1911 cm³ displacement, VW 17/1800 Type 4 style, modified hybrid engine (i.e. 1971 VW 411LE, WO-Series engine crankcase and associated internal components, NPR 96 mm bore cylinder barrels & flat-crown pistons and modified VW 1800 Type 2 cylinder heads), I determined that a deck height clearance of 1•20 ± 0•05 mm was readily attainable without machining either the crankcase or cylinder barrels, simply by omitting the steel cylinder-head sealing rings & paper cylinder-barrel-base gaskets. Sealing would be achieved, as per the VW Type 1 style engines, by lapping the tops of cylinder barrels into the cylinder heads, using fine grinding paste and a thin smear of non-setting sealant, between the cylinder barrels and crankcase.

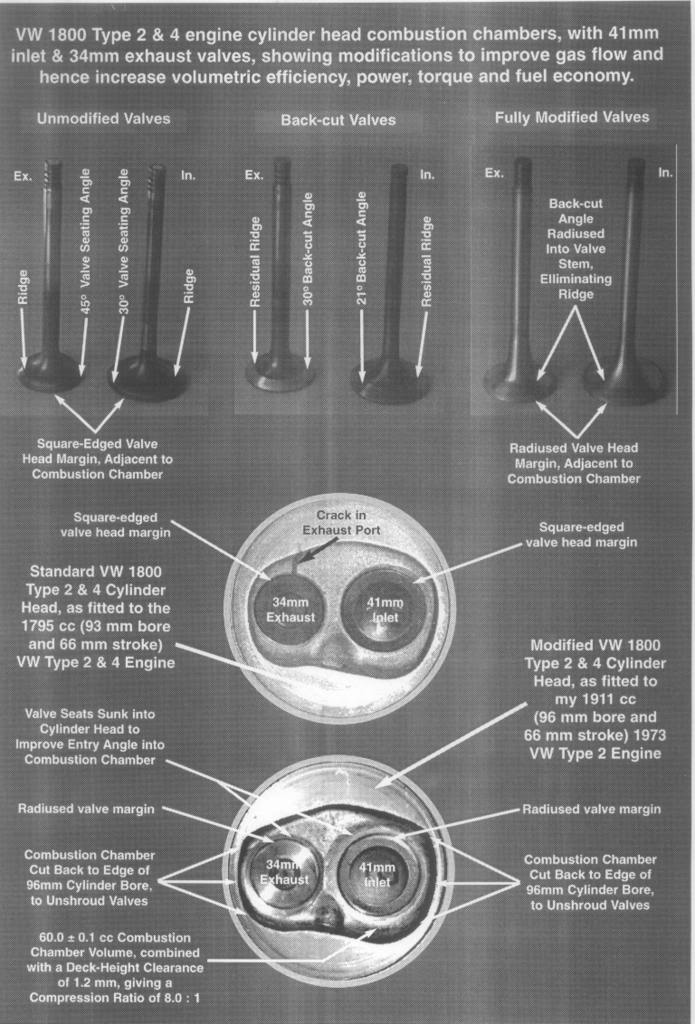

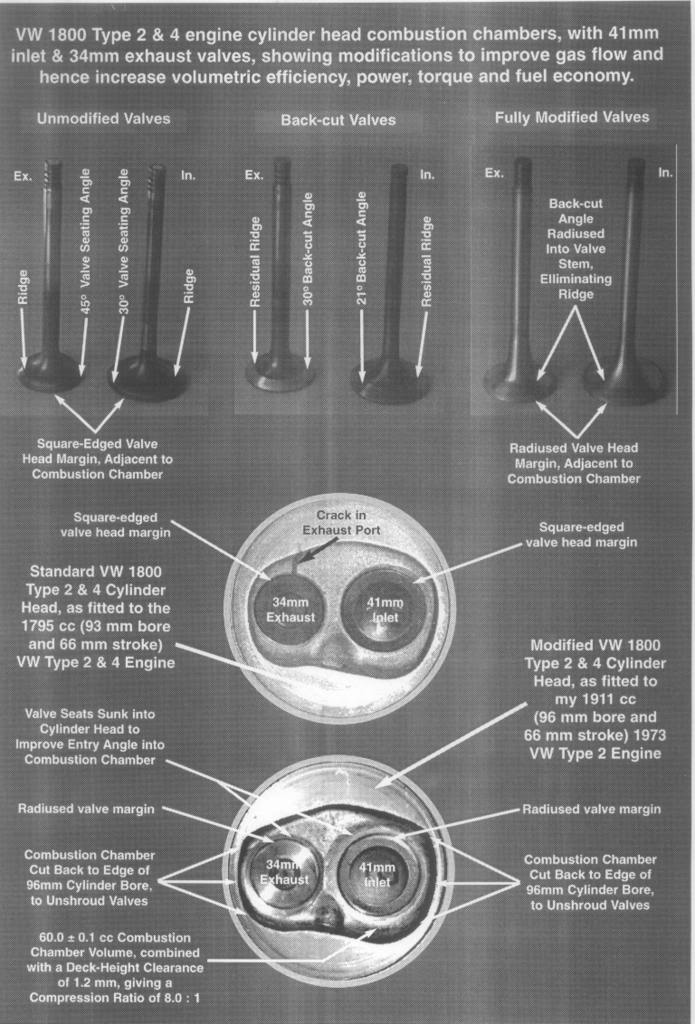

For a 1968~79 VW Type 2 engine, running on 95 RON unleaded petrol, which was becoming the norm, throughout most of the European Union, I was recommended to adopt a compression ratio of 8•0 : 1. This was achieved by increasing the combustion-chamber volume by circa 5 cm³, of the VW 1800 Type 2 cylinder heads, to 60•0 ± 0•1 cm³; unshrouding the inlet & exhaust valves, upto the inner edge of the 96 mm bore, as part of the process, for which I used rotary files on a flexible drive and cut-out cardboard patterns to check the shape. The valve heads were also reprofiled, to reduce flow resisistance, into and out of the combustion chamber.