Page 17 of 28

Re: My bug - ANGRRR - the ongoing project

Posted: Thu May 23, 2013 8:29 pm

by Tony Z

Ron, mine is a bubble case, but unfortunately the doomed and flawed first generation case...

Vader, unfortunately cutting the thread deeper will only make the crack worse. I need to stop the crack and strengthen the area.

I am busy with another small project and will only be able to get to my engine when this one is done.

Re: My bug - ANGRRR - the ongoing project

Posted: Thu May 23, 2013 8:34 pm

by retrovan

Tony Z wrote:.... am busy with another small project .......

I smell a new project, "Small" maybe a Beach Buggy.. Maybe a Original Beetle that can tow the "Trailer Queen"...

Please SIR, tell us more........

Herman

Re: My bug - ANGRRR - the ongoing project

Posted: Fri May 24, 2013 1:09 pm

by Tony Z

Sorry Herman. Its not for me, so wont be going on about it anytime soon. I am still keen to see how it turns out...

Anyway, So far today I have pulled out my engine and cleaned it up a little. Taking it one thought at a time and right now, my garage is a mess so I am not focusing on the fix just yet, got other things I want to tackle today.

Re: My bug - ANGRRR - the ongoing project

Posted: Tue Jun 25, 2013 9:30 am

by Tony Z

Yet another leave period at home over, and thus another update.

I am currently sitting at my seat covers offices waiting to be taken to the airport. So I have some time to myself while she works....

Well, as said above, near to the beginning of my time at home, I spotted an oil leak while synch'ing my carbs. I am grateful I spotted this leak in the garage, this leak turned out to be a small crack in the oil gallery where my oil hoses return from the filter and cooler back into the case.

I do have photos and will post them once I have time after I get to Europe.

OK, so I pulled out the engine and inspected the crack. I then drilled out the crack to prevent it from spreading further and then has it all welded up. A big thank you to Thumper for recommending someone who really knows his stuff with a TIG torch and filler rod.

While the engine was out I drained the gearbox oil and fitted new axle boots and a new input shaft seal. Also cleaned up a few things while I was in there...

Needless to say, I really FKN hate changing axle boots, but I did have a good pair of German boots which fits pretty well.

I also made a few small changes to the carburettors in an attempt to remove or reduce my flat spot.

So yea, to cut it short, I then put everything back together, added new oil and took her for a run.

Due to the carb changes, she runs a little lean now and thus needs another rejet, which is a job for another time, hopefully in September.

I also had the oil light come on a couple of times during my test run, which I think is from a nice big air pocket in the deep sump while I filled with oil. I originally filled the engine to half way between the min and max marks on the dipstick. After taking her for a run, I had to add over a liter of oil to get the oil level back onto the dipstick... Alas, no harm done.

So yea, happy to make progress again in a positive direction, but sad that I didnt have time to enjoy the car as I was hoping to.

Pictures to follow at some later stage...

Re: My bug - ANGRRR - the ongoing project

Posted: Tue Jun 25, 2013 9:36 am

by Thumper

Have a safe trip Tony. See you in a few..

Re: My bug - ANGRRR - the ongoing project

Posted: Tue Jun 25, 2013 9:54 am

by Loopy

Thumper wrote:Have a safe trip Tony. See you in a few..

+1 Thanks for everything!

Re: My bug - ANGRRR - the ongoing project

Posted: Tue Jun 25, 2013 11:03 am

by vader

Enjoy the break before work starts and have a blast at the wedding...

Remember to duck when the garter comes flying...

Re: My bug - ANGRRR - the ongoing project

Posted: Tue Jun 25, 2013 1:29 pm

by Ron&Gill

See you next time O Furry Fringeless one.

Re: My bug - ANGRRR - the ongoing project

Posted: Tue Jun 25, 2013 6:39 pm

by Ron&Gill

See you next time O Furry Fringeless one.

Re: My bug - ANGRRR - the ongoing project

Posted: Wed Jun 26, 2013 10:01 pm

by Tony Z

Tony Z wrote:Yet another leave period at home over, and thus another update.

I am currently sitting at my seat covers offices waiting to be taken to the airport. So I have some time to myself while she works....

Well, as said above, near to the beginning of my time at home, I spotted an oil leak while synch'ing my carbs. I am grateful I spotted this leak in the garage, this leak turned out to be a small crack in the oil gallery where my oil hoses return from the filter and cooler back into the case.

I do have photos and will post them once I have time after I get to Europe.

OK, so I pulled out the engine and inspected the crack. I then drilled out the crack to prevent it from spreading further and then has it all welded up. A big thank you to Thumper for recommending someone who really knows his stuff with a TIG torch and filler rod.

While the engine was out I drained the gearbox oil and fitted new axle boots and a new input shaft seal. Also cleaned up a few things while I was in there...

Needless to say, I really FKN hate changing axle boots, but I did have a good pair of German boots which fits pretty well.

I also made a few small changes to the carburettors in an attempt to remove or reduce my flat spot.

So yea, to cut it short, I then put everything back together, added new oil and took her for a run.

Due to the carb changes, she runs a little lean now and thus needs another rejet, which is a job for another time, hopefully in September.

I also had the oil light come on a couple of times during my test run, which I think is from a nice big air pocket in the deep sump while I filled with oil. I originally filled the engine to half way between the min and max marks on the dipstick. After taking her for a run, I had to add over a liter of oil to get the oil level back onto the dipstick... Alas, no harm done.

So yea, happy to make progress again in a positive direction, but sad that I didnt have time to enjoy the car as I was hoping to.

Pictures to follow at some later stage...

As a small follow up, here are two pics.

I thought I took more pictures, but obviously didnt...

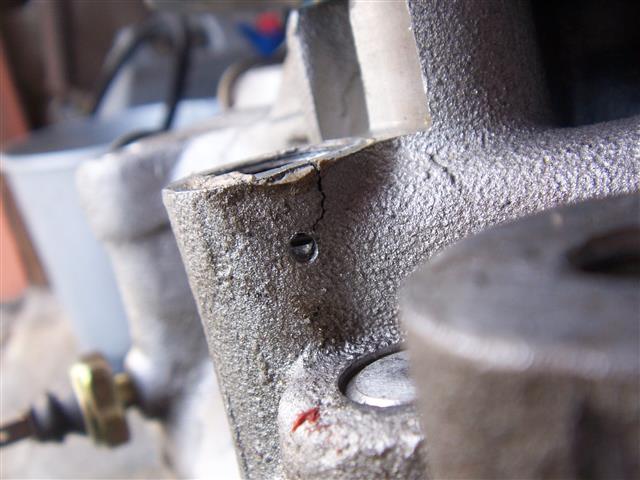

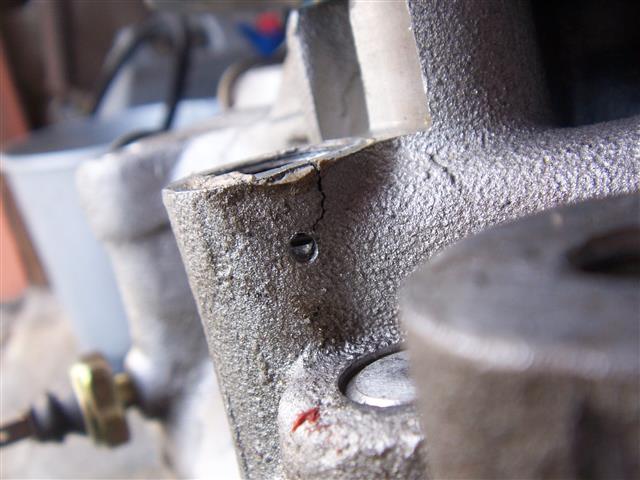

This is the crack itself. You can see I drilled a hole to stop the crack in its tracks....

for those who dont know, if you dont drill a hole into the end of a crack, it will keep going even after you have repaired it and welded it closed. The hole stops it dead in its tracks and then you can repair the crack by grinding out and welding.

Now obviously I didnt want shavings in the main oil gallery. So I made the decision: I'll put the hose fitting back into the case and drill out the crack. If the drill misses the fitting and shavings land up in the oil gallery, then I will have to strip and rebuild the engine just to be sure.

Aluminium can easily foul a bearing and thus any loose aly inside the case needs to be removed (in my case by rebuilding)...

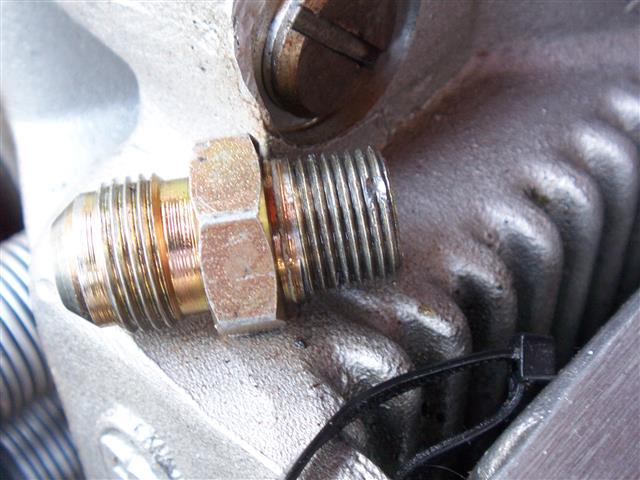

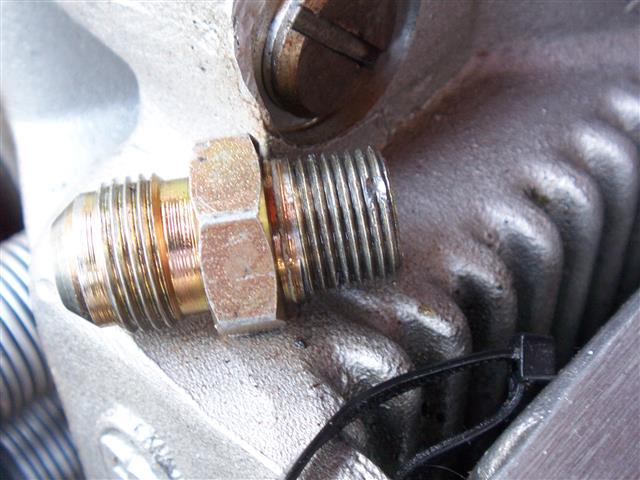

So as you can see in the picture below, the drill hit the fitting nicely, with about 1mm to spare.

1mm away from a rebuild.... so even though I didnt appreciate having to pull out the engine and fix it, I was lucky to spot the crack while I was in my garage and also lucky to not need to do a full strip and rebuild...

Maybe next holiday I'll be able to get to an event?

Re: My bug - ANGRRR - the ongoing project

Posted: Sun Jun 30, 2013 11:27 am

by Wentzel

Hi Tony I was wondering how you feel about the cam change? Was it worth it or not much difference? Hope you had a chance to at least test it. I understand that you can use more duration due to the larger capacity.

I have a C35 in the 1776 with duration of 286 and wanted to change with the new engine build, still deciding what size to go for. Maybe just cam, ratio rockers, crank and some other or whole new engine.

Hope to hear more of your project next time you're home.

Re: My bug - ANGRRR - the ongoing project

Posted: Sun Jun 30, 2013 8:53 pm

by Tony Z

In my case I think the cam change was worth it. OK, it hasnt made the engine more reliable or long life, but by the way it works at the moment, I would say I didnt have enough cam to begin with. I have pretty big heads and damn big carbs (48s) and with the cam it has now (310deg adv, 272deg actual) she pulls easily to 6500 (I am sure there is more in there) and I can putter around in 4th at 2000rpm or less and if I put my foot down a bit, she responds immediately without issue.

So in my case, yes I think it was a good choice.

Your cam is 286adv, 247actual but the car is turbo charged. Which means you dont really need or want much duration.

I once went for a drive in a 1776 that had a 110 cam (284adv, 247act) which was a riot, the only difference was he ran 1.25:1 ratio rockers. I would recommend this to anyone.

I'd look into putting higher lift onto your cam (your turbo should love it) either with a new cam or ratio rockers. Consider the C35 with 1.25:1 rockers. Also maybe think closely about the Webcam 86a (290adv, 252act) with 1.4:1 rockers. Maybe custom ground on a 109 or 110 lobe center. This will probably be a blast and will be something that very few others have considered. However, it will have less lift the the 110 with 1.25's. The C35 is similar to the 110 but has about 1mm less lift at the valve.

Me? 110 with 1.25 rockers. Well proven and reliable.

Re: My bug - ANGRRR - the ongoing project

Posted: Sun Jun 30, 2013 9:12 pm

by Wentzel

Thanks Tony I have also thought about the Engle FK 44 or 45 these have nice lift (13 to 14mm) with 1.4 rockers but wasn't sure about which duration to go for with Turbo. I'm still making up my mind about the engine and cost.

Didn't want to hi-jack.

Thanks

Re: My bug - ANGRRR - the ongoing project

Posted: Sun Jun 30, 2013 9:31 pm

by Tony Z

the fk4x series are known as crankcase killers because they are so steep (big lift for small duration). They push the cam follower pretty hard into their bores and make the bores oval.

Re: My bug - ANGRRR - the ongoing project

Posted: Mon Jul 01, 2013 10:22 am

by vader

What would extensive head work of Wenzels bug give him, like wild port and polish, bigger valves, seats and valves both with extra face angles?

With the Engle110 & 1.4:1 ratio rockers plus the head work, would this not be a bigger power payoff than just changing the cam? My thinking is more usable P trading off on MaxP....