First gear's ratio is around the same as a std beetle 2nd gear ratio. Each gear change gives a + - 1000rpm drop. Joe (Volkspares) built me one mean tranny.

My Type 1 turbo circuit racer (update pg43)

- 4agedub

- Exhaust Pipe

- Posts: 1613

- Joined: Mon Sep 19, 2005 11:36 am

- What model do you have?: Bug 1970,1972, 1974

- Location: Centurion

- Has thanked: 4 times

- Been thanked: 13 times

- Contact:

Re: My ex type 1 turbo project (Changing to Historic Racer)

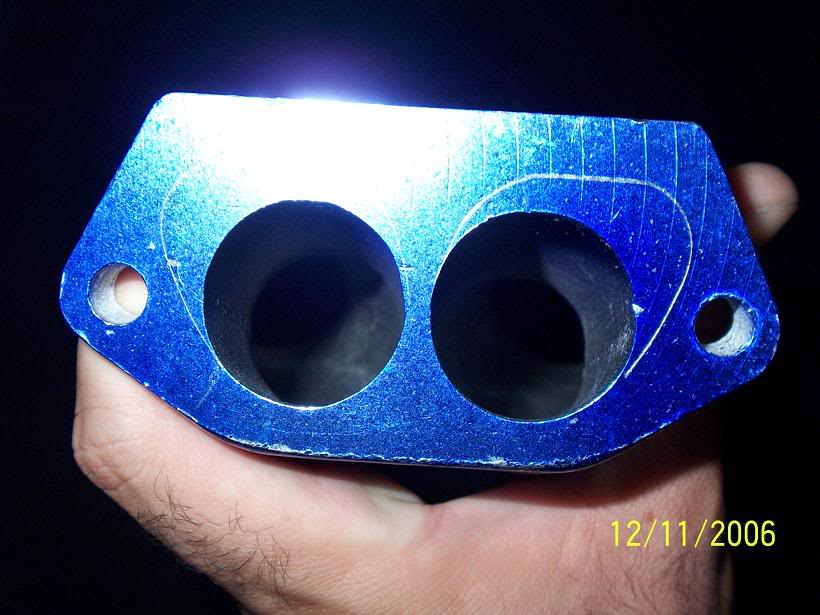

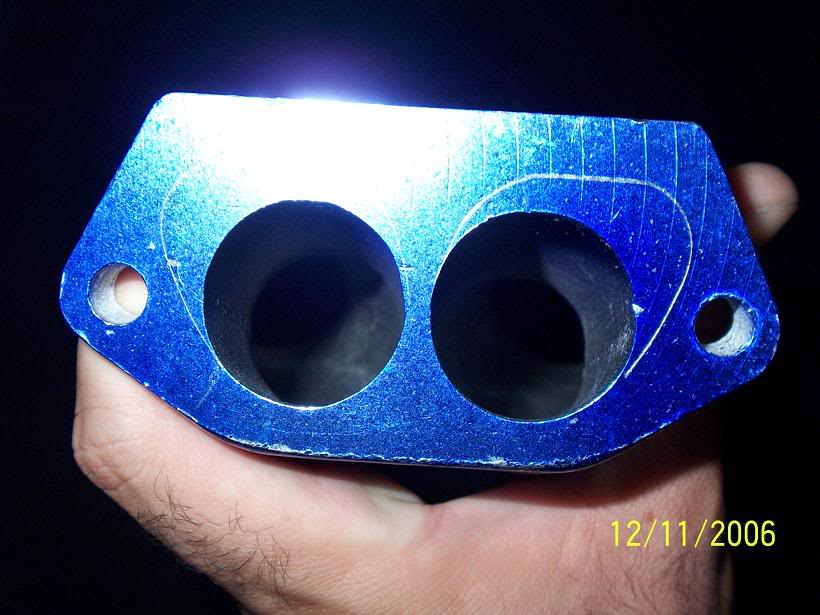

Can you say close ratio gearbox...

First gear's ratio is around the same as a std beetle 2nd gear ratio. Each gear change gives a + - 1000rpm drop. Joe (Volkspares) built me one mean tranny.

First gear's ratio is around the same as a std beetle 2nd gear ratio. Each gear change gives a + - 1000rpm drop. Joe (Volkspares) built me one mean tranny.

You do not have the required permissions to view the files attached to this post.

Last edited by 4agedub on Sat Jan 02, 2010 8:10 pm, edited 1 time in total.

VW Beetle 1303 - 2165cc Turbo

VW Beetle 1971 2332cc

VW Beetle 1969 - 2666cc Turbo

VW Beetle 1974 - 1600

VW Beetle 1971 2332cc

VW Beetle 1969 - 2666cc Turbo

VW Beetle 1974 - 1600

- 4agedub

- Exhaust Pipe

- Posts: 1613

- Joined: Mon Sep 19, 2005 11:36 am

- What model do you have?: Bug 1970,1972, 1974

- Location: Centurion

- Has thanked: 4 times

- Been thanked: 13 times

- Contact:

Re: My ex type 1 turbo project (Changing to Historic Racer)

Here's a datalog around zwartkops. Coming out of turn 2, through 3 into turn 4.

Turn 2, 1st gear. Just after turn 3 4th gear.

Turn 2, 1st gear. Just after turn 3 4th gear.

You do not have the required permissions to view the files attached to this post.

VW Beetle 1303 - 2165cc Turbo

VW Beetle 1971 2332cc

VW Beetle 1969 - 2666cc Turbo

VW Beetle 1974 - 1600

VW Beetle 1971 2332cc

VW Beetle 1969 - 2666cc Turbo

VW Beetle 1974 - 1600

- Tony Z

- Donor

- Posts: 15009

- Joined: Wed Sep 14, 2005 8:33 am

- What model do you have?: 2.3L 69; 1302; P/Van

- Location: Klipheuwel (near Durbanville), Cape Town or working at sea

- Has thanked: 192 times

- Been thanked: 488 times

Re: My ex type 1 turbo project (Changing to Historic Racer)

those gears are pretty close...

Were you not going to be running FI???

Were you not going to be running FI???

ANGRRR

http://www.aircooledvwsa.co.za/viewtopi ... 23&t=14775

1302S

http://www.aircooledvwsa.co.za/viewtopi ... 23&t=33521

Panel Van

http://www.aircooledvwsa.co.za/viewtopic.php?p=288723

http://www.aircooledvwsa.co.za/viewtopi ... 23&t=14775

1302S

http://www.aircooledvwsa.co.za/viewtopi ... 23&t=33521

Panel Van

http://www.aircooledvwsa.co.za/viewtopic.php?p=288723

vader wrote: The Force is strong with you young Sith Lord Z!

- 4agedub

- Exhaust Pipe

- Posts: 1613

- Joined: Mon Sep 19, 2005 11:36 am

- What model do you have?: Bug 1970,1972, 1974

- Location: Centurion

- Has thanked: 4 times

- Been thanked: 13 times

- Contact:

Re: My ex type 1 turbo project (Changing to Historic Racer)

I really tried to convince the committee to allow me run fuel injection. After numerous letters and a + - 100 page folder showing that fuel injection was available for beetle's from the factory, they decided that it would not be allowed. So then my next option is 48ida's, which I've already got

TonyZ I've still not ported my 044 heads... how big do you think I should go with the intake ports?? Also how did you make all your ports equal when grinding them open??

TonyZ I've still not ported my 044 heads... how big do you think I should go with the intake ports?? Also how did you make all your ports equal when grinding them open??

VW Beetle 1303 - 2165cc Turbo

VW Beetle 1971 2332cc

VW Beetle 1969 - 2666cc Turbo

VW Beetle 1974 - 1600

VW Beetle 1971 2332cc

VW Beetle 1969 - 2666cc Turbo

VW Beetle 1974 - 1600

- Tony Z

- Donor

- Posts: 15009

- Joined: Wed Sep 14, 2005 8:33 am

- What model do you have?: 2.3L 69; 1302; P/Van

- Location: Klipheuwel (near Durbanville), Cape Town or working at sea

- Has thanked: 192 times

- Been thanked: 488 times

Re: My ex type 1 turbo project (Changing to Historic Racer)

I would say you need to make them pretty big, but not so big that you need to weld the CB 044s.

Make a cardboard template with only one port cut-out of it and use that to mark the shape of the inlet port. --- this is in the same place as the manifold gasket.

Then as you port, make sure you do the things one step at a time. Then do that step to each cylinder before doing the next step. Be warned, this will take you a lot longer than you first think. Keep keeping all the ports looking the same. then when you are done, put the valves in with a little vaseline and measure the cc of the port. Make them all pretty much the same and try to find the differences between them as you go.

I'll look for a pic of my port shape - it turns out to be very similar to the wedge port shape, just a tiny bit smaller.

Make a cardboard template with only one port cut-out of it and use that to mark the shape of the inlet port. --- this is in the same place as the manifold gasket.

Then as you port, make sure you do the things one step at a time. Then do that step to each cylinder before doing the next step. Be warned, this will take you a lot longer than you first think. Keep keeping all the ports looking the same. then when you are done, put the valves in with a little vaseline and measure the cc of the port. Make them all pretty much the same and try to find the differences between them as you go.

I'll look for a pic of my port shape - it turns out to be very similar to the wedge port shape, just a tiny bit smaller.

ANGRRR

http://www.aircooledvwsa.co.za/viewtopi ... 23&t=14775

1302S

http://www.aircooledvwsa.co.za/viewtopi ... 23&t=33521

Panel Van

http://www.aircooledvwsa.co.za/viewtopic.php?p=288723

http://www.aircooledvwsa.co.za/viewtopi ... 23&t=14775

1302S

http://www.aircooledvwsa.co.za/viewtopi ... 23&t=33521

Panel Van

http://www.aircooledvwsa.co.za/viewtopic.php?p=288723

vader wrote: The Force is strong with you young Sith Lord Z!

- Tony Z

- Donor

- Posts: 15009

- Joined: Wed Sep 14, 2005 8:33 am

- What model do you have?: 2.3L 69; 1302; P/Van

- Location: Klipheuwel (near Durbanville), Cape Town or working at sea

- Has thanked: 192 times

- Been thanked: 488 times

Re: My ex type 1 turbo project (Changing to Historic Racer)

on this thread http://www.aircooledvwsa.co.za/viewtopi ... 23&t=14775

you will find this pic

I used a 1mm thick piece of cardboard from the back of a writing pad. I then copied a stock steel manifold gasket onto it and cut it out so that the bolt holes fit perfectly and cut one stock port hole into it. Then marked out the shape I wanted the port to look like and cut the cardboard accordingly. Then trace that shape onto the head. If it look right, use it, if not, then re-shape.

Remember that to straighten the port, you need to move it closer to the bolt holes and dont touch the dimple at the bottom - thats the spring land.

Good luck and keep pics coming

you will find this pic

I used a 1mm thick piece of cardboard from the back of a writing pad. I then copied a stock steel manifold gasket onto it and cut it out so that the bolt holes fit perfectly and cut one stock port hole into it. Then marked out the shape I wanted the port to look like and cut the cardboard accordingly. Then trace that shape onto the head. If it look right, use it, if not, then re-shape.

Remember that to straighten the port, you need to move it closer to the bolt holes and dont touch the dimple at the bottom - thats the spring land.

Good luck and keep pics coming

ANGRRR

http://www.aircooledvwsa.co.za/viewtopi ... 23&t=14775

1302S

http://www.aircooledvwsa.co.za/viewtopi ... 23&t=33521

Panel Van

http://www.aircooledvwsa.co.za/viewtopic.php?p=288723

http://www.aircooledvwsa.co.za/viewtopi ... 23&t=14775

1302S

http://www.aircooledvwsa.co.za/viewtopi ... 23&t=33521

Panel Van

http://www.aircooledvwsa.co.za/viewtopic.php?p=288723

vader wrote: The Force is strong with you young Sith Lord Z!

- 4agedub

- Exhaust Pipe

- Posts: 1613

- Joined: Mon Sep 19, 2005 11:36 am

- What model do you have?: Bug 1970,1972, 1974

- Location: Centurion

- Has thanked: 4 times

- Been thanked: 13 times

- Contact:

Re: My ex type 1 turbo project (Changing to Historic Racer)

Thanks Tony. I'll upload pics as I progress.

VW Beetle 1303 - 2165cc Turbo

VW Beetle 1971 2332cc

VW Beetle 1969 - 2666cc Turbo

VW Beetle 1974 - 1600

VW Beetle 1971 2332cc

VW Beetle 1969 - 2666cc Turbo

VW Beetle 1974 - 1600

- 4agedub

- Exhaust Pipe

- Posts: 1613

- Joined: Mon Sep 19, 2005 11:36 am

- What model do you have?: Bug 1970,1972, 1974

- Location: Centurion

- Has thanked: 4 times

- Been thanked: 13 times

- Contact:

Re: My ex type 1 turbo project (Changing to Historic Racer)

I'm resurrecting an old thread here

So after five years of historic racing I've decided to change back to turbo and go race in another series.... maybe silver cup or super saloons. Over the past year I've collected some parts for this build and hope to have it running by Feb 2014.

Here's some pics of the engine build so far:

CB Performance 78.4mm cromoloy crankshaft with straight cut cam gears and H-beam connecting rods

So after five years of historic racing I've decided to change back to turbo and go race in another series.... maybe silver cup or super saloons. Over the past year I've collected some parts for this build and hope to have it running by Feb 2014.

Here's some pics of the engine build so far:

CB Performance 78.4mm cromoloy crankshaft with straight cut cam gears and H-beam connecting rods

You do not have the required permissions to view the files attached to this post.

VW Beetle 1303 - 2165cc Turbo

VW Beetle 1971 2332cc

VW Beetle 1969 - 2666cc Turbo

VW Beetle 1974 - 1600

VW Beetle 1971 2332cc

VW Beetle 1969 - 2666cc Turbo

VW Beetle 1974 - 1600

- 4agedub

- Exhaust Pipe

- Posts: 1613

- Joined: Mon Sep 19, 2005 11:36 am

- What model do you have?: Bug 1970,1972, 1974

- Location: Centurion

- Has thanked: 4 times

- Been thanked: 13 times

- Contact:

Re: My ex type 1 turbo project (Changing to Historic Racer)

Auto linea ally engine case machined for 94mm barrels

You do not have the required permissions to view the files attached to this post.

VW Beetle 1303 - 2165cc Turbo

VW Beetle 1971 2332cc

VW Beetle 1969 - 2666cc Turbo

VW Beetle 1974 - 1600

VW Beetle 1971 2332cc

VW Beetle 1969 - 2666cc Turbo

VW Beetle 1974 - 1600

-

flatfourfan

- Full-time Bug Nutter

- Posts: 4195

- Joined: Tue Nov 08, 2005 12:06 pm

- What model do you have?: Speedster Replica

- Location: Pretoria

- Has thanked: 36 times

- Been thanked: 50 times

Re: My ex type 1 turbo project (Changing to Historic Racer)

how come you decided to change race series? I was always enjoyed watching your cabby in the historic series.

- 4agedub

- Exhaust Pipe

- Posts: 1613

- Joined: Mon Sep 19, 2005 11:36 am

- What model do you have?: Bug 1970,1972, 1974

- Location: Centurion

- Has thanked: 4 times

- Been thanked: 13 times

- Contact:

Re: My ex type 1 turbo project (Changing to Historic Racer)

CB 044 Super pro cnc ported cylinder heads

You do not have the required permissions to view the files attached to this post.

VW Beetle 1303 - 2165cc Turbo

VW Beetle 1971 2332cc

VW Beetle 1969 - 2666cc Turbo

VW Beetle 1974 - 1600

VW Beetle 1971 2332cc

VW Beetle 1969 - 2666cc Turbo

VW Beetle 1974 - 1600

- 4agedub

- Exhaust Pipe

- Posts: 1613

- Joined: Mon Sep 19, 2005 11:36 am

- What model do you have?: Bug 1970,1972, 1974

- Location: Centurion

- Has thanked: 4 times

- Been thanked: 13 times

- Contact:

Re: My ex type 1 turbo project (Changing to Historic Racer)

My dad's car will still be racing historics next year. But both our cars will be outlawed from 2015 with the new engine capacity rules. The new rules say engine capacity may only be increased by 15%. Which means 1817cc max.flatfourfan wrote:how come you decided to change race series? I was always enjoyed watching your cabby in the historic series.

VW Beetle 1303 - 2165cc Turbo

VW Beetle 1971 2332cc

VW Beetle 1969 - 2666cc Turbo

VW Beetle 1974 - 1600

VW Beetle 1971 2332cc

VW Beetle 1969 - 2666cc Turbo

VW Beetle 1974 - 1600

- splitfan

- Carburettor

- Posts: 1966

- Joined: Fri Jul 20, 2007 1:23 pm

- What model do you have?: 56,71,75

- Location: Port Shepstone KZN

- Has thanked: 46 times

- Been thanked: 26 times

- Contact:

Re: My ex type 1 turbo project (Changing to Historic Racer)

This is gonna be a beast ! keep the pics coming

My biggest fear is that my wife sells my cars for what i told her they cost !!

- 4agedub

- Exhaust Pipe

- Posts: 1613

- Joined: Mon Sep 19, 2005 11:36 am

- What model do you have?: Bug 1970,1972, 1974

- Location: Centurion

- Has thanked: 4 times

- Been thanked: 13 times

- Contact:

Re: Type 1 turbo circuit racer

Yesterday we assembled the engine to this point. There's a lot of measuring and engineering involved with a build like this.

This is the first engine that I'm using 10mm cylinder head studs and copper rings in the heads... so that added up to the build time as well.

This is the first engine that I'm using 10mm cylinder head studs and copper rings in the heads... so that added up to the build time as well.

You do not have the required permissions to view the files attached to this post.

VW Beetle 1303 - 2165cc Turbo

VW Beetle 1971 2332cc

VW Beetle 1969 - 2666cc Turbo

VW Beetle 1974 - 1600

VW Beetle 1971 2332cc

VW Beetle 1969 - 2666cc Turbo

VW Beetle 1974 - 1600

- 4agedub

- Exhaust Pipe

- Posts: 1613

- Joined: Mon Sep 19, 2005 11:36 am

- What model do you have?: Bug 1970,1972, 1974

- Location: Centurion

- Has thanked: 4 times

- Been thanked: 13 times

- Contact:

Re: My ex type 1 turbo project (Changing to Historic Racer)

Pauter 1.4:1 roller rockers installed

You do not have the required permissions to view the files attached to this post.

VW Beetle 1303 - 2165cc Turbo

VW Beetle 1971 2332cc

VW Beetle 1969 - 2666cc Turbo

VW Beetle 1974 - 1600

VW Beetle 1971 2332cc

VW Beetle 1969 - 2666cc Turbo

VW Beetle 1974 - 1600