Update 14 Dec 09:

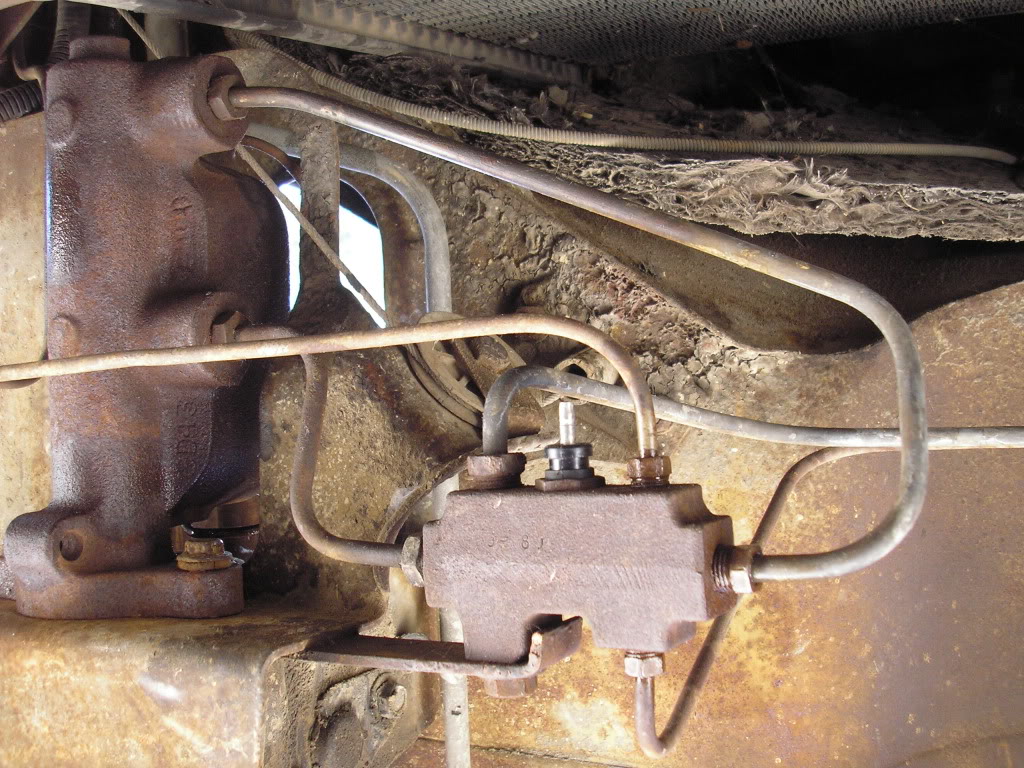

Between Saturday and today, I got all the plumbing needed for the brakes - it is A LOT of pipes, but in a nutshell

- 2 x standard male to female brake hoses from the callipers inwards

- 2 x galvanised clips to secure the rubber hoses to the chassis mounts

- 1 long, 1 short steel pipe from the front hoses to the m/c

- 1 shortened centre steel line, running on the right-hand side of the transmission tunnel, to the rear

(this is where it gets interesting)

- from the center steel line, to the r/h T-piece

- one arm of the T to a custom short male to female rubber hose (IRS, remember - standard Beetle short hoses are female to female)

- rubber hose to r/h rear steel line, running on the trailing arm to the r/h rear slave cylinder

- other arm of the r/h T-piece to a steel line, jumps accross the gearbox, to the l/h T-piece

- 2 x galvanised clips to secure the rubber hoses to the trailing arm mounts (total of 4, instead of normal 6 on a Beetle)

- center of l/h T-piece blocked off

- other arm of l/h T-piece goes to short another custom male to female rubber hose

- from the short rubber hose, another steel line on the l/h trailing arm to the l/h rear slave cylinder

The master cylinder is an early Citi unit, dual stage, with a matching reservoir that fits snugly on top of the m/c rubber grommets. The m/c has no less than EIGHT (8) holes!

After some dry-fitting, this is how I plan to route the plumbing from the 8 holes of the m/c:

Front stage

Top - fluid reservoir front chamber

Left - l/h brake calliper

Bottom - r/h brake calliper

Right - brake switch

Rear stage

Top - fluid reservoir

Left - blanked off (against the transmission tunnel anyway)

Bottom - blanked off

Right - rear brake circuit

The front left part of the m/c is also very close to the transmission tunnel, so IMPI suggest that I route the steel line of the l/h calliper

through the tunnel, instead of jumping it accross, like a standard Beetle. This seems like a good suggestion, I only need to get some rubber grommets for where the steel line goes through the tunnel, after drilling two holes through it.

I am halfway through the fitting of all the lines, but the darkness caught me, will probably continue tomorrow, first need to spray the master cylinder though (hope the sun shines tomorrow afternoon!), as it is currently bare metal and will rust on the outside with the slightest moist...

After all the plumbing is connected, the next big step will be to bleed the brakes, I am a little bit worried about the rear slave cylinders, as I couldn't find the correct Type 3 ones, for the wider rear Type 3 drums and backing plate. The issue is that the bleeding nipple is now

below the steel line (Beetle slave cylinders), so I just hope a bubble doesn't get cought somewhere it can't get out. Another option will be to bleed the rear brakes from behind

- but I have never done that before.

The advantage of the dual circuit system is that the front and the rear brakes will work completely independently, so if one circuit fail, the other will still work 100%.... in other words no sickening feeling of slamming on brakes, only to find there aren't any

Pics to follow soon....