Line boring

- IMPI

- Donor

- Posts: 1897

- Joined: Wed Sep 14, 2005 9:01 pm

- What model do you have?: sp2

- Location: Orkney Northwest province

- Has thanked: 1 time

- Been thanked: 78 times

Line boring

Line boring of beetle engines used to be done by every jan rap en sy maat back in the old days. One Rand could buy two american dollars those days and getting a set of Hunger reamers were easy and semi affordable They would pay for themselfes within ten engines and were state of the art in the sixties. The reamers were adjustable and relied heavily on operator skills to ensure that they cut the correct size hole and make that hole round. both things not easy to achieve with a worn reamer. I the days that these were designed cases were meant to be cut 0.25mm or maximum 0.5 mm and the reamer for the small bearing (closest to the pulley) was meant to cut the pulley bore as well hence the need for an oversized pulley. were you not to push the reamer through completely in order to re use that standard pully the bore was cut tapered and it was only the lightly stressed bearing that could live with this.

Later on the americans dispensedwith reamers and made line bore tools which operated like a big line boring machine with cutting bits pre set for use. all of these systems used the front bore and the rear oil seal surface to line up the machine. there was several types of mechanisms used in order to feed the bits and ensure a clean cut. these machines needed less skills to set up but if the feed mechanism was misused a bad cut resulted.

I have had cause to use both types of line bore tools and eventually got fed up with he non repeatability of all these reamers and tools

I found an old line boring machine originally made in the cape by a company called GUSWIN (I wonder if they still exist) I was not happy with their boring bar which was too flimsy in my opinion but I lked the custom feed mechanism and the fact that it was a big robust and sturdy machine It cost me R10000 I spoke to a few of the top VW people I know and desided to re design the actuall cutters I bought brite shaft (the stuff hydraylic cylinders are made off and had them modified for tungsten carbide cutting tips) I made bars for 0.5mm 1.0mm 1.5mm 2.0mm and 2.5mm which are the sizes for which bearings can be found. I found a std case which had othe r problems causing it to be junk and spent almost a week cutting and adjusting until I found the correct sizing for each size. needles to say I am he only one who uses them

The total cost ended up being just shy of R20000 and I will probably never recoup it in my life but As with the Impi Shroud I did it for the love of it.

when you are in the market for a line boring job you need to understand a few things:

Firstly the casing is more than 30 years old......

It has had its share of abuse.

ONE casing out of twenty might not need a line bore

they wear in places and distort in places where other engines have no places.

some rebuilders skimmed casings regardles meaning that the distrubutor drive gear was als cut ceep them together (competition motors were fond of this but all rebuilders does it even REMTEC

cases have cracks and you need to search for them

AS 41 cass distort around the center main (torque the empty case and see if there is a gap in the center main saddles (if it passes light it is in need of serious repair.

All saddles can distort if that main seized

the bearing dowels need to be tight but can be repaired.

the rear main flywheel side also wears on the thrust surface but can be cut 2mm undersize it needs to be wider than 200 mm for repairs to be effective

From wear the cam tunnel distorts on all cases and needs to be resized normally to standard but watch for that odd (usually ex genuine vw recon that have oversize cam bearings (if you have a few sets I want them please)

some rebuilders VW included installed spacers behind bearings or bored bearing journals to different oversizes measure twice.

the pulley side bearing has a very tricky set up and is usually blocked ensure all oil galeries are open otherwise you will rebuild almost immediately

Check for stripped studs every where

check that oil control pistons are loose and will function

As can be seen it is false economy to try and do the block unless you are really know VW,s and the correct procedures

Ask about the machinest knowledge speak to people who has used his services.

Remember most reamers are worn out by this time

If he uses a drill press to guide the reamer walk away

Ask if he bores all journals

ask about the thrust surface and cam tunnel if they seem unsure they usually are.

Armand

Later on the americans dispensedwith reamers and made line bore tools which operated like a big line boring machine with cutting bits pre set for use. all of these systems used the front bore and the rear oil seal surface to line up the machine. there was several types of mechanisms used in order to feed the bits and ensure a clean cut. these machines needed less skills to set up but if the feed mechanism was misused a bad cut resulted.

I have had cause to use both types of line bore tools and eventually got fed up with he non repeatability of all these reamers and tools

I found an old line boring machine originally made in the cape by a company called GUSWIN (I wonder if they still exist) I was not happy with their boring bar which was too flimsy in my opinion but I lked the custom feed mechanism and the fact that it was a big robust and sturdy machine It cost me R10000 I spoke to a few of the top VW people I know and desided to re design the actuall cutters I bought brite shaft (the stuff hydraylic cylinders are made off and had them modified for tungsten carbide cutting tips) I made bars for 0.5mm 1.0mm 1.5mm 2.0mm and 2.5mm which are the sizes for which bearings can be found. I found a std case which had othe r problems causing it to be junk and spent almost a week cutting and adjusting until I found the correct sizing for each size. needles to say I am he only one who uses them

The total cost ended up being just shy of R20000 and I will probably never recoup it in my life but As with the Impi Shroud I did it for the love of it.

when you are in the market for a line boring job you need to understand a few things:

Firstly the casing is more than 30 years old......

It has had its share of abuse.

ONE casing out of twenty might not need a line bore

they wear in places and distort in places where other engines have no places.

some rebuilders skimmed casings regardles meaning that the distrubutor drive gear was als cut ceep them together (competition motors were fond of this but all rebuilders does it even REMTEC

cases have cracks and you need to search for them

AS 41 cass distort around the center main (torque the empty case and see if there is a gap in the center main saddles (if it passes light it is in need of serious repair.

All saddles can distort if that main seized

the bearing dowels need to be tight but can be repaired.

the rear main flywheel side also wears on the thrust surface but can be cut 2mm undersize it needs to be wider than 200 mm for repairs to be effective

From wear the cam tunnel distorts on all cases and needs to be resized normally to standard but watch for that odd (usually ex genuine vw recon that have oversize cam bearings (if you have a few sets I want them please)

some rebuilders VW included installed spacers behind bearings or bored bearing journals to different oversizes measure twice.

the pulley side bearing has a very tricky set up and is usually blocked ensure all oil galeries are open otherwise you will rebuild almost immediately

Check for stripped studs every where

check that oil control pistons are loose and will function

As can be seen it is false economy to try and do the block unless you are really know VW,s and the correct procedures

Ask about the machinest knowledge speak to people who has used his services.

Remember most reamers are worn out by this time

If he uses a drill press to guide the reamer walk away

Ask if he bores all journals

ask about the thrust surface and cam tunnel if they seem unsure they usually are.

Armand

Who cares how it's done in California?

(018) 473-0186

- fig

- Bus Driver

- Posts: 12214

- Joined: Fri Jan 20, 2006 10:08 pm

- What model do you have?: Type 2

- Facebook: https://www.facebook.com/groups/258896479219/

- Location: Where life is cheap and death is free

- Has thanked: 287 times

- Been thanked: 322 times

- Contact:

Re: Line boring

Great stuff Armand. I think everyone who reads this should send you money!

fig

Kaapse Kombi Kult

"Whether you think you can or whether you think you can't, you're right." -- Henry Ford

Kaapse Kombi Kult

"Whether you think you can or whether you think you can't, you're right." -- Henry Ford

-

Bad Ass Bob

- Carburettor

- Posts: 1924

- Joined: Tue Aug 07, 2007 3:27 pm

- What model do you have?: ZILTCH

- Facebook: www.facebook.com/brandon.gilson

- Location: Port Elizabeth

Re: Line boring

I think we should send cases and money at least recupe something, awsome info ,

thanks BAB

thanks BAB

Bad Ass ???

- davetapson

- Oil Cooler

- Posts: 341

- Joined: Sun May 24, 2009 9:49 pm

- What model do you have?: Type 1's '63 and '66

- Facebook: www.facebook.com/davetapson

- Location: Gauteng

- Contact:

Re: Line boring

Hi Armand

Would you be prepared to do cases for us? If so, do you got a price in mind?

Regards

Dave

Would you be prepared to do cases for us? If so, do you got a price in mind?

Regards

Dave

My project: http://www.aircooledvwsa.co.za/viewtopi ... 23&t=12543" onclick="window.open(this.href);return false;

Looking for a splitscreen panelvan - have a year or two to find one. If you know of one, please let me know.

Looking for a splitscreen panelvan - have a year or two to find one. If you know of one, please let me know.

- IMPI

- Donor

- Posts: 1897

- Joined: Wed Sep 14, 2005 9:01 pm

- What model do you have?: sp2

- Location: Orkney Northwest province

- Has thanked: 1 time

- Been thanked: 78 times

Re: Line boring

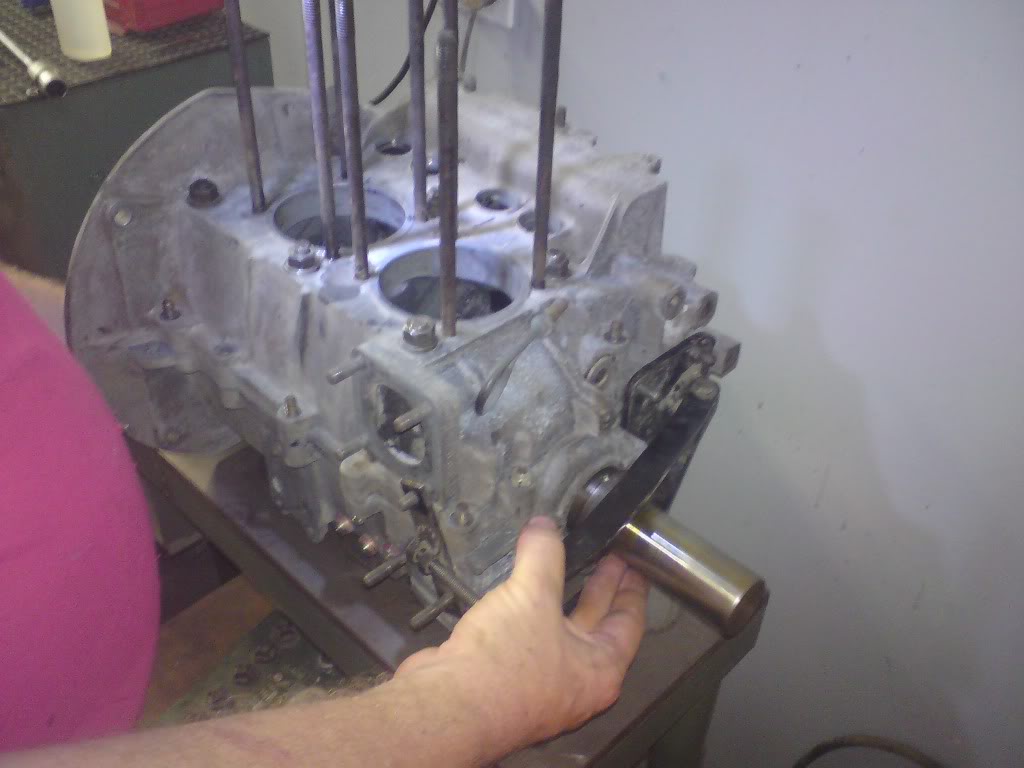

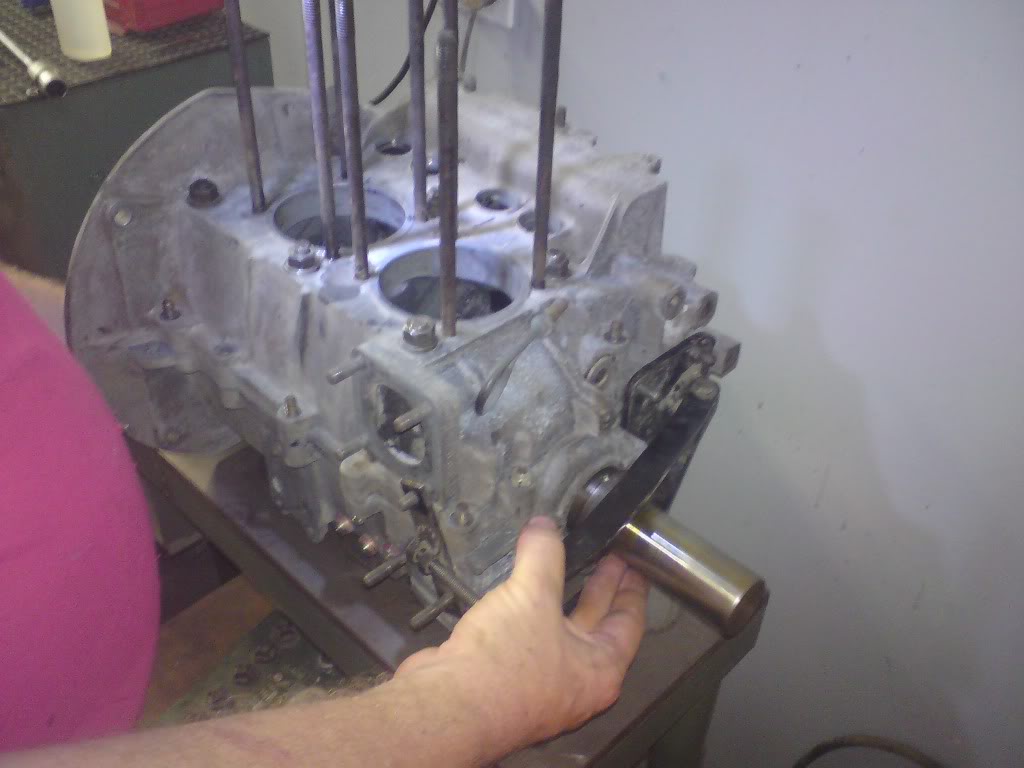

Had some time to take photos of the typical ine boring job.

First off the cases need to be really clean.

If you can see bearing numbers etched in the case it will need a linebore.

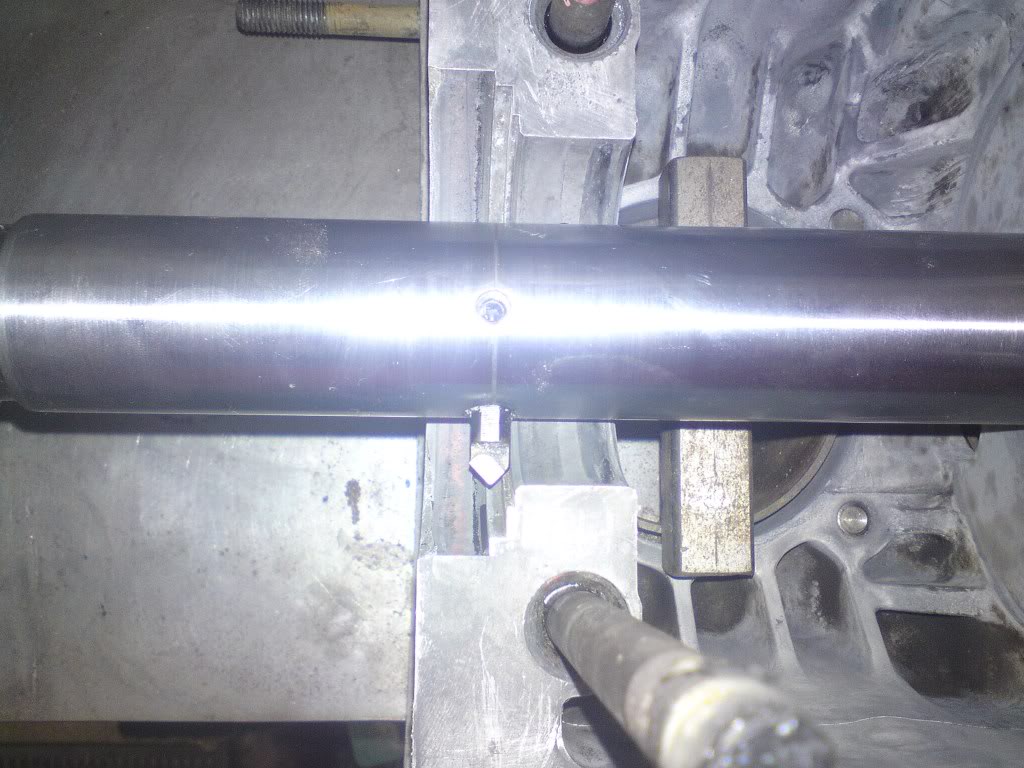

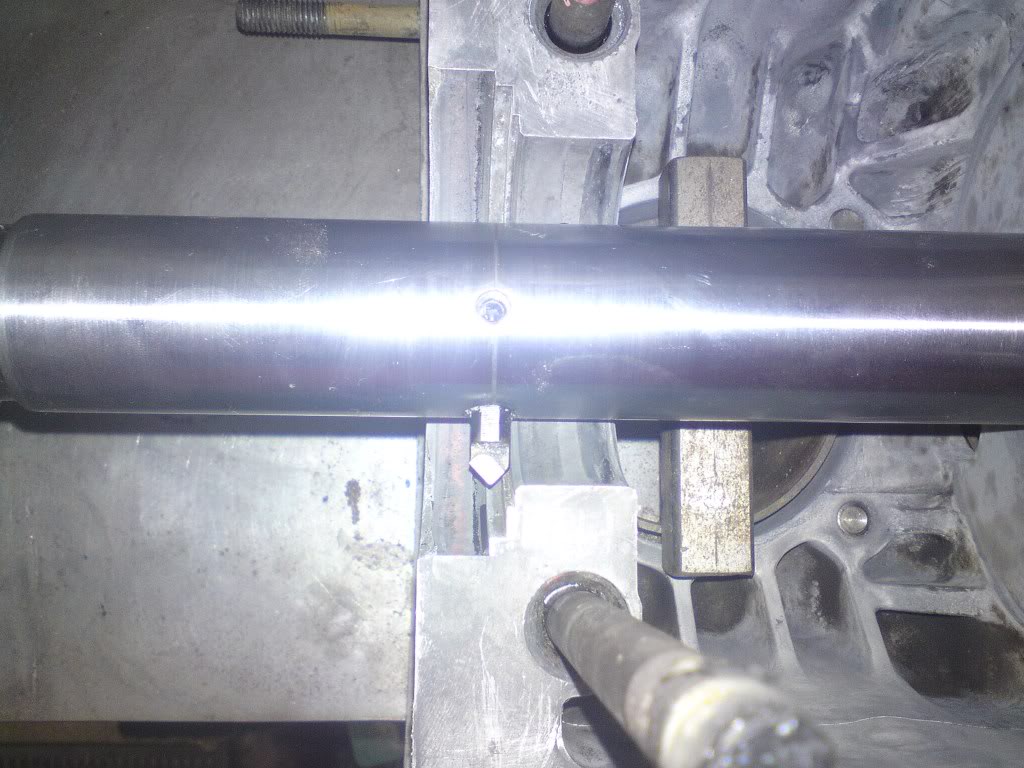

case on the machine bar in place

detail of the tungsten carbide cutter

rear guide picking up on oil seal surface

The other end

A universal joint is used in order to minimise outside interference from machine

case is torqued to vw spec. ( I like using this genuine VW torque wrench)

A special fixture is used to keep tool in position.

I hold my hand on the bar whilst cutting as any vibration or problems during the cut is felt immediately

The completed cut

as can be seen from the extremely fine shavings a very small cut is taken per revolution

The final product is simply gorgeous.

Armand

First off the cases need to be really clean.

If you can see bearing numbers etched in the case it will need a linebore.

case on the machine bar in place

detail of the tungsten carbide cutter

rear guide picking up on oil seal surface

The other end

A universal joint is used in order to minimise outside interference from machine

case is torqued to vw spec. ( I like using this genuine VW torque wrench)

A special fixture is used to keep tool in position.

I hold my hand on the bar whilst cutting as any vibration or problems during the cut is felt immediately

The completed cut

as can be seen from the extremely fine shavings a very small cut is taken per revolution

The final product is simply gorgeous.

Armand

Who cares how it's done in California?

(018) 473-0186

-

ZeroAxe

- Drive Train

- Posts: 3004

- Joined: Tue Feb 21, 2006 12:07 am

- What model do you have?: FUmobile

- Location: It doesn't matter.

- Been thanked: 1 time

Re: Line boring

Wow. I love seeing things like this. Well done! One question though? How do you adjust the depth of the carbide cutter? Vernier, dial-guage, other(s)? And what do you use to drive the bar/cutter? Speed? Etc? well, actually more than one question realy!

VW Enthusiast

- Ron&Gill

- Full-time Bug Nutter

- Posts: 4054

- Joined: Fri Aug 29, 2008 4:16 am

- What model do you have?: Type 1, 21b, 34, 316

- Location: St Lucia KZN/Cameron LA

- Has thanked: 1 time

- Been thanked: 21 times

Re: Line boring

What he said... And how do you know to cut 0.5 or 1 or 1.5 etc mm? Are you able to measure the distortion of the block and then calculate the depth of the cut? How does the cutter move horizontaly (from right to left?), by turning the wing nuts? Or does the drive do it?ZeroAxe wrote:Wow. I love seeing things like this. Well done! One question though? How do you adjust the depth of the carbide cutter? Vernier, dial-guage, other(s)? And what do you use to drive the bar/cutter? Speed? Etc? well, actually more than one question realy!

Thanks for taking the time to add the pictures, I learnt a lot from them...

1964 T34 - The Razor: viewtopic.php?f=23&t=10290

1956 T2 1b - Gill's bus: viewtopic.php?f=23&t=10948

1967 T316 - viewtopic.php?f=23&t=10931 & viewtopic.php?f=23&t=15977

2000 beach buggy - viewtopic.php?f=23&t=10915

1956 T2 1b - Gill's bus: viewtopic.php?f=23&t=10948

1967 T316 - viewtopic.php?f=23&t=10931 & viewtopic.php?f=23&t=15977

2000 beach buggy - viewtopic.php?f=23&t=10915

- sarel.wagner

- Pushrod

- Posts: 966

- Joined: Sat Dec 26, 2009 6:10 pm

- What model do you have?: T1 x 4, Split SCwide

- Facebook: http://www.facebook.com/sarel.wagner

- Location: Centurion

- Been thanked: 2 times

- Contact:

Re: Line boring

Eat your hats Remtec! This is class right here. Do you need to line bore type 4 cases or don't they wear in the same way?

Rgrds

Rgrds

New Konzept (o\ ! /o) Build Blog: http://konzeptdrei.blogspot.com/

T1 in '63 '67 '73 and Rusty a '71, DC Bay (sold), Variant, T2 '75 SC Fleetline Wide loadbed splittie

What other people think of you is none of your damn business

T1 in '63 '67 '73 and Rusty a '71, DC Bay (sold), Variant, T2 '75 SC Fleetline Wide loadbed splittie

What other people think of you is none of your damn business

- vader

- ACVWSA Junkie

- Posts: 6465

- Joined: Mon Sep 19, 2005 9:17 am

- What model do you have?: TieFighter

- Location: Help!I don't know where I am. Its dark & I can hear voices...

- Has thanked: 9 times

- Been thanked: 10 times

Re: Line boring

Thanks for the info IMPI, jew da man with the plan! I was going to post a picture for you to show my appreciation but didn't want to sturr up the hornets nest again so you just gonna have to be happy with this...

I do have a very technical question IMPI?

Where does the bicycle pump plug in?

I do have a very technical question IMPI?

Where does the bicycle pump plug in?

IMPI wrote:

"My other ride is your SeatCover! & She loves it!"

Sometimes you'r the statue, sometimes your the pigeon.

"Only the dead go free..." Roger Waters.

"You do not understand the power of the DarkSide" Darth Vader.

Sometimes you'r the statue, sometimes your the pigeon.

"Only the dead go free..." Roger Waters.

"You do not understand the power of the DarkSide" Darth Vader.

-

calooker

- Donor

- Posts: 4973

- Joined: Wed Sep 14, 2005 9:24 am

- What model do you have?: 77 SP

- Location: Johannesburg

- Has thanked: 5 times

- Been thanked: 98 times

- Contact:

Re: Line boring

It's good to know that there are dudes out there who are prepared to do that little bit extra.IMPI wrote:

AS 41 cass distort around the center main (torque the empty case and see if there is a gap in the center main saddles (if it passes light it is in need of serious repair.

All saddles can distort if that main seized

Armand

Not pissing on your parade, but these are my views.

I prefer to rather have a case refaced, I insist on it, and use a undersize cam drive as then there is no issues with any distorted saddles, there will be no need for oversize cam bearings as the cam bore gets bored as well, it's a hell lot more work but well worth it in the long run, the other benefits is a fresh seating surface for the main seal, very often get damaged when gorilla force & intelligence is used to remove a leaky seal. The oil pump then also has a fresh mating surface with no drop in oil pressure due to previous distortion or careless removal or instillation. The mating surface is now also true & less likely to leak. Another reason is the resized cam drive is now to spec and not worn due to years of use, as the material is rather soft.

When refacing the case less than 0,2mm is machined off so the affect on CR is not an issue.

BTW

The bearing dowels are for locating the bearings, the crush of the casing once bolted together is what holds the bearings in place, the dowels are there so you don't fit the bearings incorrectly.

For what it's worth, ignorance has no limits ......

- IMPI

- Donor

- Posts: 1897

- Joined: Wed Sep 14, 2005 9:01 pm

- What model do you have?: sp2

- Location: Orkney Northwest province

- Has thanked: 1 time

- Been thanked: 78 times

Re: Line boring

Hi all

I use a modified micrometer to measure the tip and it took hours and quite a few old cases in order the get the adjustments spot on.

As for refacing the case halfs i am equipped to do that machining but have found it to be a very difficult proposition to do accurately enough to be able to do it on a production type basis.

I believe that it was even a problem for the factory if one measures how many cranks don actually sit in the centerline of the casing. I have seen cases that took more than 0.5mm ( and have seen 2mm thick spacers and very small timing gears on those silver painted engines with the plate rivited to the block) to face all the distortion problem is you now sit with a few oval faces which are not easy to get centered as you have (1) the wear which caused the need for a line bore and the oval created when you bring the halves closer together getting the center of your cutting tool centered in that banged up hole is a bitch and easier to get slightly wrong than right then you cut the front pully bore as well as the oil seal bore only then your fixture takes up on those holes and you bore the main bores. the next hurdle is the cam tunnel now also oval and the same battle starts again only this time you want it as parrallel to the crank as possible. finally you need to bore the oil pump hole which now needs to be parralle to the crank and the cam center line.

whilst it is true that it is great to start with all new bearing surfaces the possibility of mistake is much greater.

since I am always trying to learn as much as possible I recently took a nearly perfect casing to one of the best in JHB to skim and line bore ( First time in my life) I wanted to be able to mike and check afterwards and obviously compare my work to them.

Whilst the work was done to a very high std those same issues that bothers me also is an issue with them The oil pump hole is definitely off a very small amount ie not parralle to the old bores. and they informed me that the crank is now measurably off center and I had to compensate when making the cylinder spacers. So I am obviously not the only one finding the centering difficult.

I think that it pays to be very dilligent in checking the case be absolutely sure about warpage and then compensate by machining the problem but I also dont fix what aint broke

I use a modified micrometer to measure the tip and it took hours and quite a few old cases in order the get the adjustments spot on.

As for refacing the case halfs i am equipped to do that machining but have found it to be a very difficult proposition to do accurately enough to be able to do it on a production type basis.

I believe that it was even a problem for the factory if one measures how many cranks don actually sit in the centerline of the casing. I have seen cases that took more than 0.5mm ( and have seen 2mm thick spacers and very small timing gears on those silver painted engines with the plate rivited to the block) to face all the distortion problem is you now sit with a few oval faces which are not easy to get centered as you have (1) the wear which caused the need for a line bore and the oval created when you bring the halves closer together getting the center of your cutting tool centered in that banged up hole is a bitch and easier to get slightly wrong than right then you cut the front pully bore as well as the oil seal bore only then your fixture takes up on those holes and you bore the main bores. the next hurdle is the cam tunnel now also oval and the same battle starts again only this time you want it as parrallel to the crank as possible. finally you need to bore the oil pump hole which now needs to be parralle to the crank and the cam center line.

whilst it is true that it is great to start with all new bearing surfaces the possibility of mistake is much greater.

since I am always trying to learn as much as possible I recently took a nearly perfect casing to one of the best in JHB to skim and line bore ( First time in my life) I wanted to be able to mike and check afterwards and obviously compare my work to them.

Whilst the work was done to a very high std those same issues that bothers me also is an issue with them The oil pump hole is definitely off a very small amount ie not parralle to the old bores. and they informed me that the crank is now measurably off center and I had to compensate when making the cylinder spacers. So I am obviously not the only one finding the centering difficult.

I think that it pays to be very dilligent in checking the case be absolutely sure about warpage and then compensate by machining the problem but I also dont fix what aint broke

Who cares how it's done in California?

(018) 473-0186

-

Kaptein

- Oil Pump

- Posts: 271

- Joined: Sat Jun 23, 2012 4:20 pm

- What model do you have?: Baywindows & Beetles

- Location: West rand,Gauteng

- Has thanked: 2 times

- Been thanked: 8 times

Re: Line boring

Hi, just need some advise regarding a case.

I recently bought a AS41 case engine with the intention of stroking it to a bigger capacity...

And after reading a bit on here, now I'm not so sure if this is a good base to start with? The case has been painted silver and has the little plate riveted to the top like you explained and it had quite thick barrel spacers on left side of the engine (dizzy side)

Also the engine no seems like it was mashined of an new no knocked on but has little vw emblem on either side of the engine no

So it seems to me that this was a vw rebuilt engine and with that said not a good base to start with?

I recently bought a AS41 case engine with the intention of stroking it to a bigger capacity...

And after reading a bit on here, now I'm not so sure if this is a good base to start with? The case has been painted silver and has the little plate riveted to the top like you explained and it had quite thick barrel spacers on left side of the engine (dizzy side)

Also the engine no seems like it was mashined of an new no knocked on but has little vw emblem on either side of the engine no

So it seems to me that this was a vw rebuilt engine and with that said not a good base to start with?

- IMPI

- Donor

- Posts: 1897

- Joined: Wed Sep 14, 2005 9:01 pm

- What model do you have?: sp2

- Location: Orkney Northwest province

- Has thanked: 1 time

- Been thanked: 78 times

Re: Line boring

Hi even thse casingse are sometimes OK to use but you need to check it carefully. I prefer to build performance engines on casings which were not rebuilt previously and have found that SFAD coded casings are some of the nicest used casings around (why that is I cant explain but they started out as single port 1600s and might have had an easier life as a result.

check the main bearing thrust surface if it is less than 21mm wide againt not really suitable.

Post up a few Photos so that we can give a better opinion

check the main bearing thrust surface if it is less than 21mm wide againt not really suitable.

Post up a few Photos so that we can give a better opinion

Who cares how it's done in California?

(018) 473-0186

- buggyfan

- Long Block

- Posts: 2979

- Joined: Wed Mar 12, 2008 2:26 am

- What model do you have?: lwb beachbuggy

- Location: newlands,jhb

- Has thanked: 95 times

- Been thanked: 87 times

Re: Line boring

Very informative post regarding line boring a type1 casing

@Impi thanks for going through the effort of explaining the process and taking pics aswell

@Impi thanks for going through the effort of explaining the process and taking pics aswell

http://www.aircooledvwsa.co.za/viewtopi ... tt#p269451" onclick="window.open(this.href);return false;