In this post I have placed copies of Emails as well as posts on various forums which have been saved on my hard drive I did not correct spelling in those posts and have chaged the font colour to red.. I also took Photos from various sources and only posted them to provide visual confirmation for illustrating what I am talking about. I thank everybody whose Photos I have used for their contribution and if there is any problem I will remove the offending photo.

This came about last weekend when somebody told two gentlemen enquiring about the upright conversion in my Westy. that it is a system copied by myself from Jake Raby in the US (as Jake claims) When I explained how it came about we parted with understanding and I am not upset with this individual.

First a bit of history:

I have been around VW’s since the early seventies.I was building an upright conversion (using the Volkspares housing) in 1988 and only stopped doing that when I sold the bug to further other interests (my Significant other) I built my first large Type 4 for a fastback in 1997 using home made converted Deutz sleeves and Chevy pistons This engine powered my 411 with a turbo later on. Ever since the Type 4 which I abandoned in 1988, due to it not fitting easily, it bugged me getting a big engine in the tail of a beetle.

We then had a tour from Orkney to Margate with beetles in December 1999 (about 700km) and a buddy of mine went down with a beetle with a 2.4 liter Type 4 and a converted beetle set-up to cool the engine almost like the Joe Cali method but this fan housing was sectioned and used the “down the middle” cooling concept which we saw in the adverts of a guy named Joe Locicero of Oregon Performance products who came up with the idea. As the set-up worked fairly well in Neels’s car, we were bench racing on the beach one night and the following criteria was discussed:

We didn’t like the fact that the down the middle shroud moved the oil cooler and there was potential leaks involved with hoses.

We didn’t like the fact that the oil cooler was effectively mounted upside down which would be the ideal place to trap sludge (after all the DTM’s sold, these fears seems to be groundless)

We wanted the engine compartment sealed and and did not like the piece of flat aluminium used By Joe. (Neels used flat sheet and this cut the sealing rubber badly during our trip)

We decided that the alternator stand needed to be cast as this will be the neatest solution.

When the beetle fan housing for Neels's car was cut open in order to kink it for the dtm idea, we saw lots of internal vanes on the inside left hand side of the engine and none on the right hand side. This led us to the belief that the smaller left hand box of Joe’s design was not as good as it could be. Lastly we didn’t like the fact that the rear (front of engine) area where the fan fitted through the housing wasn’t shaped the same as the area on a beetle fan housing. Joe made it that way in order to use a one piece mould presumably for ease of production.

Early in January of 2000 I started by placing a type four engine on a stand and a pile of type four sheet metal and an old dog house fan housing.

I then built my interpretation of the fan housing from metal and body putty incorporating all the ideas we discussed and quite a few I discovered along the way. Being a gold miner and Having Mine ventilation as a subject was a great help as it allowed me to figure out exactly why the engineers in Wolfsburg did what they did when they designed the Beetle cooling system. A few of the ventilation specialists on the mine became interested in my project and many details were discussed at length.

When the final prototype was made the only idea I had in common was the fact that I incorporated Joe’s idea of centering the outlets on the fan down the middle of the cylinder banks as he did when he designed the DTM fan housing.

Remember at this stage Jake Raby,s system did not feature at all yet, Joe was still the owner and inventor of this concept.

Joe Locicero sadly passed away in 2002 before we could make contact as I really wanted to ask him questions and by all accounts he was a good guy always willing to push the envelope. I then contacted Jake with a few questions and suggestions from my experience in July 2002. Here follows my letter: I included pictures and an explanation of my thought processes:

From: Botha, Armand ( GNM )

Sent: Tuesday, July 30, 2002 1:43 PMTo: '

Subject: My type 4 conversion

Hi Jake

Read about you in the STF pity about the mud slinging.

As it is extremely expensive in South africa to get overseas parts I decided to build my own conversion.

I based the conversion on a late beetle doghouse shroud and a combination of other parts. I also studied the info about other conversions and must admit that I copied some features (notably the Dtm confuguration.) As can be seen from my photos i incorporated all the type one vanes into the shroud. I also kept the volumes almost the same as VW ( this may not be very important as the DTM is almost the exact opposite of the (mirror image) and is reported to work well) I moved the Fan centerline closer to the center line of the case for two reasons. I wanted to use a stock belt and the type 4 is slightly narrower than a type 1 i used 4 type 4 covers to hug the cyliders and added ledges for compartment sealing. I used a duct to channel air to the stock cooler and this removes a lot of complexity for a near stock engine. the front and rear breast plates are also fibreglass and gives an almost stock look to the compartment. I also made a duct which can place the cooler in the same position as a stock type 1. The one completed unit has now been running daily for seven months and is totally trouble free running cooler than the std type 1 it replaced. some other features: cast stand taking either a alternator or a generator.

Machined steel pulley for reliability and wear resistance. same size as a late doghouse pulley.

Lining up all the vanes and fitting the fan inside the curved duct at the back of the housing(front of car) is a real pain but I believe it was worth it. As you can see from the photos there are lots of other home made parts on the engine eg. manifolds, linkage, airfilters, exhaust Interim) and a conversion flywheel.

A question

As the DTM fanshroud places the cooler upside down and there is not very much space at the top inside the cooler could high mileage no cause sludge buildup and finally blockage of the cooler?

Hope to be able to pick your Brain in future as well

Regards

Armand Botha

Orkney South Africa.

Due to some re design on my part I was not able to send a copy of my Shroud to Jake and decided to make my shroud public but only before contacting him again

-----Original Message-----

From: Jake Raby [mailto:rabysvw@linkamerica.net]

Sent: Monday, December 09, 2002 8:41 PM

To: Botha, Armand ( GNM )

Subject: Re: your address

Armand,

There is a huge desire for a better shroud than a DTM, as the DTM is almost

unpurchasable these days since Joe died.

my address is 47 Raby Drive, Cleveland Georgia 30528 USA.

I will test if and may be interested in purchaisng them from you

Jake Raby

Raby's Aircooled Technology

http://www.aircooledtechnology.com

see our customer forum at

http://www.germanlook.com/Forums/forumd ... forumid=29

----- Original Message -----

From: "Botha, Armand ( GNM )" <AWBotha@AngloGold.com>

To: <jake@aircooledtechnology.com>

Sent: Monday, December 09, 2002 12:27 PM

Subject: your address

> hi Jake

> I am planning to send you one of my fanhousings early in January but I

need

> your addres to send to.

>

> As I found some clearance issues with my first set I am now rebuilding the

> mould in order to cater for the thickness of the fiberglass. I would like

to

> know how much wider than a standard engine I should allow for ie cylinder

> spacer thickness as it would be easy to cater for in the new mould. the

set

> I will be sending is still from the present moulds and thus is a very

tight

> fit around the cylinders.

> Find attached a few photos of my newest toy soon to have one of my

> conversions.

> Regards

> Armand <<My German look Beetle.ppt>>

Then came this Post on the STF and I decided not to send a shroud.

posted 12-31-2002 12:06 PM

subject: Mold Purchase

Vince,

Please understand that for my business to continue that I must have shrouds. You have tried your best to supply the shrouds like your dad did, but it is apparent that the profit or desire are not there for you as you already have other aspects of life to keep bread on the table, and you specialize in other areas. My need for these shrouds is much like your need of a supplier for radiators for your engines, without it you can do nothing.

I want to make you one last a serious offer to buy those molds for the shroud and take over the business from you before I go any further with my plans for my own shroud. My shroud will be based on the same idea of your dads, but WILL have attachment differences, and physical changes that will make it different from a DTM, it also will not have the DTM name or implications and will be marketed differently, most likely only on my engines. You know that Brent and I are the most proficient people on earth with that shroud, we have learned from it and adhered to its design, quite possibly we may be more experienced with it that even your dad was in its fit and function. I know that you realize that as you looked to us for upgrades to its design, and even the harware it uses and the contents of the kit.

Please do not think I'm trying to be a vulcher, I had (and still do) a great deal of respect for your dad, he was willing to sell me the shroud business and offered to before he passed, it never was able to happen, time was not on our side. Your dad gave me the idea to be a pioneer with the TIV world, and for that I will always be grateful.

I'm writing this note to you, and will be publically displaying it to make one final attempt to purchase the molds and rights to the Oregon Performance DTM shroud before embarking on my own venture of design and manufacturing. I can only hope that if you do not wish to do these shrouds any longer that you will read this email and make contact with me so we can further the transaction. Almost everyday that goes by another person ids forced away from the TIV or settles for a different, less effective method of cooling, due to the fact that the DTM or a version of it is not available.

I have already made my decision to make my own shroud, with or without the molds and rights to the shroud that your dad designed. If you decide to keep the molds we will become competitors, but I hope we can remain friends. I will ensure that your dads work on the shroud design will not be forgotten, I will always associate your dad(and always will give him credit) with the ioriginal idea of the DTM Upright conversion shroud. You have my word on that.

I'm only doing what I must do to keep the TIV engine conversion strong, I have given the TIV engine years of my life and cannot stand by and watch it go down hill at its strongest point due to the problems that have happened recently. I also cannot let such a simple aspect of the conversion make so many people continue to pour money into disposable TI engines when they really need an effective TIV resolution for their application.

Please make contact with me ASAP and let me know your thoughts on the purchase, one way or the other, positive or negative. My contact information is (w) 706 865 1963 (H) 706 219 4874 (C) 706 892 8192 and you have this email address to reply to.

I look forward to your reply, and can only hope that you will sell me those molds and rights so that I can keep the legacy alive, it will life much easier for everyone involved, and you can benefit monetarily by selling the molds at the same time, else they may sit around and collect dust, that would be a sad thing.

Sincerely,

Jake Raby

Owner

Raby's Aircooled Technology http://www.aircooledtechnology.com/

see our customer forum at http://www.germanlook.com/Forums/forumd ... forumid=29

------------------

Jake Raby

Raby's Aircooled Technology

http://www.aircooledtechnology.com

A whole round of mud slinging went on amongst people on the STF and I kept out of it. End of story and Jake became the owner of the DTM Moulds by using a third party to purchase the moulds as advertised on the net

I posted details of my take on the cooling system early in 2003 in the Shoptalk Forums:

Included in this post was a series of Photos detailing the internal workings of the shroud and how it works. Mr Jake Raby commented on copycats in an unrelated post just after I posted this post and I sent him a mail trying to clear the air. I also decided not to send him a copy of the shroud for what seemed to me a valid reason after he failed to reply to my letter.

Jake Raby

Samba Member

Joined: August 23, 2003

Posts: 4319

Jake Raby is offline

PostPosted: Today 7:13 am Post subject: Reply with quote Report this post to Moderator/Admin.

As long as the production numbers stay low and kits are not sold in the US or any of the countries where my largest numbers of customers for the DTM are I won't take things further..

However, the "confusing similarities" within the details of the IMPI system are enough to justify action on behalf, if and when I see fit.

I find Armand's indirect slams at my kit in his descriptions un-necessary and them alone are enough for me to take things to the next level.

Whether or not the unit is a direct copy or not, it does have some of the same characteristics that the DTM design is recognized for.

I prepare in advance for situations like this and will deal with them swiftly and aggressively when they occur.

Jakes final Post:

Ok...

You asked for it...

I'll be turning this over to Legal today.

Thanks for the reminder that I should have done it long ago.

Smart ass comments don't get anywhere with me.

Gloves are off, tell Armand to get ready for a trip to Georgia that he'll be paying for and it won't be a Vacation.

Once upon a time armand admitted that he purchased a DTM shroud from Joe Locicero to study for the development of his unit. That piece of evidence is held in my data base and will be used as "Exhibit A"..

I would like to refer here to my letter to Mr Raby where I offered to send him one of my shrouds and as to where his evidence came from I don’t understand as this is what I said to him:

I also studied the info about other conversions and must admit that I copied some features (notably the Dtm confuguration.) As can be seen from my photos i incorporated all the type one vanes into the shroud. I also kept the volumes almost the same as VW ( this may not be very important as the DTM is almost the exact opposite of the (mirror image) and is reported to work well) As he read something into this which was clearly not so I never heard from him again.

Then The following was Posted in 2004:

MASSIVE TYPE IV Post subject:

Posted: Wed Jan 28, 2004 7:18 am

Joined: Fri Jul 07, 2000 2:01 am

Posts: 20345 The stock shroud testing is happening today... We'll see if the flaps and lower control plenums make a difference.

Just last evening I was able to make contact with Mr. Bob Hoover. For those of you who don't know Mr. Hoover, he is a well very well versed older gentleman that knows more abouut the VW than anyone I have ever made contact with.... He and Joe used to talk when Joe was building the shrouds as they were near the same age and had about the same experiences in life. He was able to que me in on some things that I previously did not know about Joe's design work and testing.

Heck, Mr. Hoover even knew the correct name for the airfoils that VW used as vanes in the stock shroud- "Eipper 300 series"- it blew me away. He and I discussed the ways to correctly measure the pressures in each side of the shroud. It seems that an airspeed indicator with a relocateable pitot tube will do the trick.. Here is a excerpt from an email he wrote me..

" Depending on air density and fan speed, the pressure differential should be equal to between six and 9 inches of water. (Not a bunch; 6" H2O is about 3psi; 9" is about 4.4 [you'd better check that. I'm old; I fart a lot and forget things.])"

So it looks as if this is getting more complex everyday- Now I can see more and more the reasons why the 911 fan doesn't do what it should for these engines! we'll see tomorrow just what it can do!

BTW, the Editor from Ultra VW magazine has expressed interest in doing the coverage of the test work- They are from England, and have so far been the only "Fair" publication that was willing to talk to us!

These changes were made in 2004 and they look like the original vanes installed in My shroud from 2000. My vanes were also copied from original VW vanes but due to production constraints didn’t end up looking like the original VW vanes. I searched for the "Eipper 300 series" airfoil design and found that Eipper was an American builder of light aircraft and started operations in 1972 but could not find any of the rest of the details. Interestingly VW released the first dog house shrouds in 1971.

Other important changes were made to incorporate a diffuser venturi to the back of the shroud a feature found on my first prototype.

I found an interesting Corvair (Chevrolet air cooled flat 6) design study from the early sixties that made me think about the origins of the OPP shroud. Whilst all of this is conjecture the design of the Chevrolet cooling system is very similar to Joe’s design and from what I have read he was a very innovative person who had wide interests. Whilst it looks like the DTM is a mirror image of the Corvair set up it must be remembered that the Corvair engine turns anti clockwise and would account for that.

I can categorically state that I have never copied the DTM shroud nor have I ever seen one in the flesh (only in Photos) I feel this confusion has gone on long enough and the following facts may clear up any of the confusion still remaining.

1. VW came up with the original designs for cooling Type one and Type 4 engines with air.

2. General Motors copied the VW layout when they built the Corvair.

3. The Late Joe Locicero of Oregon performance products was the originator of the DTM fan shroud

4. I Armand Botha looked at all the available designs and built the IMPI fan shroud starting in 2000 and had it running

before Air cooled technology acquired the DTM design

5. Joe’s Son Vince did not want to sell the moulds and related equipment (I don’t know for what reason) to Jake Raby,

Jake got a third party to purchase the moulds and Jigs and owns them fair and square

Air Cooled Technology has done a lot of research and testing on the DTM and subsequently incorporated a few changes to the shrouds

As can be seen It would appear that The Pot is calling the kettle black. I have never claimed copyright on my Fan housing. I have never threatened anybody with court. I haven’t used my time in the Military to try and scare anyone. And I have always been open with the whys and wherefores of my design.

I don’t have a beef with Jake or anyone for that matter. I just don’t like it when people accuse me of copying the DTM fan shroud when those same people has no claim to have designed a cooling system themselves. I still own the prototype shroud and am able to prove that I built the plug with my own two hands. I did use the Down The Middle concept ideas from the Late Joe Locicero and will acknowledge that. I also did take 99 percent of the way VW designed the late beetle cooling system and used it. I Also used my Own knowledge as someone trained in the use of cooling fans and used it.

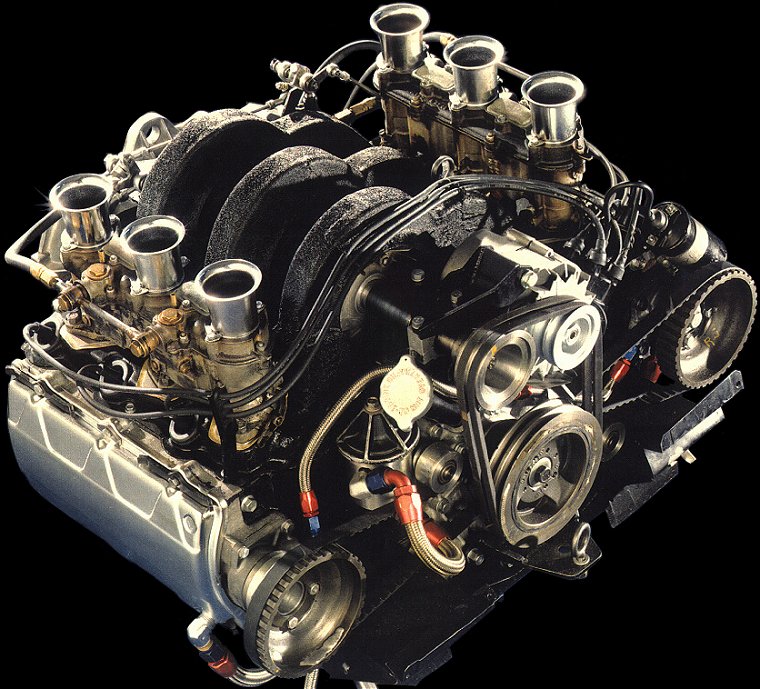

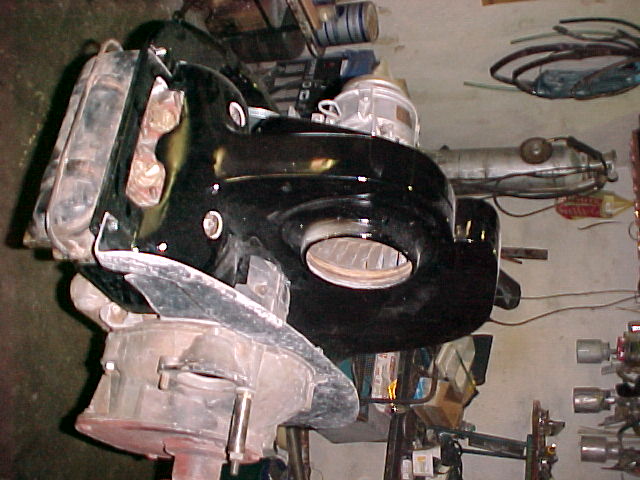

These are a set of Photos of specific details inside my fanshrouds which are not present in any DETM past or present:

Internal vanes as copied from VW and posted in 2003

Oil cooler ducts incorporated in engine sealing "tin"

Fully enclosed front of engine showing air venturi on fan

DTM for comparison

Cast stand for alternator and also pattern made by me

Full impi kit

Full OPP Kit

Lastly a complete impi and a complete Aircooled technology engine Let the differences speak for themselves.

Same engine type same cooling fan but different solutions.

I do not want to open a debate on the issue and will not add further comments to this post either. I now hope the record is straight and we can all get on with our respective lives.

Thank You for reading this

Armand Botha